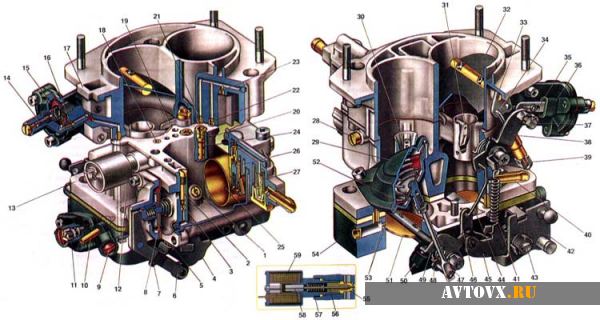

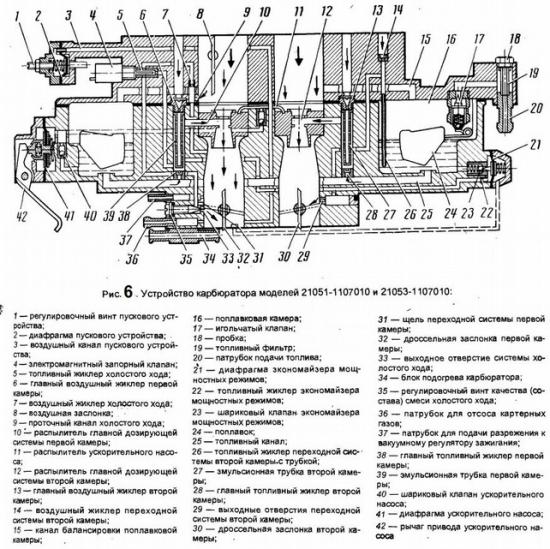

Scheme of the carburetor "Ozone"

1 - screw for adjusting the stroke of the inlet valve of the accelerator pump; 2 - carburetor cover; 3 - fuel jet of the transition system of the second chamber; 4 - air jet of the transition system; 5 – econostat air jet; 6 – econostat fuel jet; 7 - the main air jet of the second chamber; 8 - emulsion jet econostat; 9 - pneumatic actuator of the throttle valve of the second chamber; 10 - small diffuser; 11 - jets; 12 - delivery valve of the accelerating pump; 13 - accelerator pump sprayer; 14 - air damper; 15 - the main air jet of the first chamber; 16 - jet starting device; 17 - air jet idle move; 18 - automatic starting device; | 19 - solenoid valve with idle fuel jet; 20 - needle valve for fuel supply; 21 - fuel filter; 22 - fuel supply fitting; 23 - float; 24 - screw for factory adjustment of the idle system; 25 - the main fuel jet of the first chamber; 26 - adjusting screw for the quality of the working mixture; 27 - adjusting screw of the composition of the working mixture; 28 - throttle valve of the first chamber; 29 - body of the float chamber; 30 - throttle valve of the second chamber; 31 - throttle body; 32 - emulsion tube; 33 - main fuel jet of the second chamber; 34 - bypass valve of the accelerator pump; 35 - inlet valve of the accelerator pump; 36 - accelerator pump drive lever. |

|

Design description

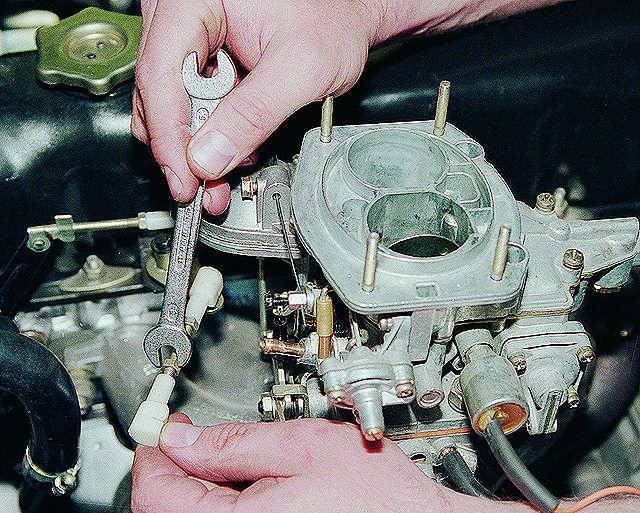

On the VAZ-2106 car, the Ozone carburetor of the DAAZ 2107-1107010-20 model is currently being installed. On a VAZ-21065 car, a DAAZ 21053-1107010 carburetor is used (a model based on the Solex carburetor family). Carburetor "Ozone" - emulsion type, two-chamber, with a falling stream. It has one balanced float chamber, two main metering systems, an enrichment device (econostat) in the second chamber, an autonomous idle system, transition systems of the first and second chambers, a diaphragm accelerator pump with a spray in the first chamber, an idle system solenoid shut-off valve, a spool crankcase gases removal device into the throttle space, pneumatic actuator of the throttle valve of the second chamber. The control of the air damper of the first chamber is manual, with a cable drive. After starting the engine, the damper is automatically opened by a diaphragm-type starting device under the action of a vacuum in the intake piping. The carburetor is equipped with a vacuum outlet to control the ignition timing controller. Fuel is supplied to the carburetor through a strainer and needle valve. The valve is mechanically connected to the float and maintains a certain level of fuel in the float chamber. From the float chamber, fuel enters through the main fuel jets (of the first and second chambers) into the emulsion wells and emulsion tubes, where it mixes with air entering through the main air jets. The air-fuel emulsion enters through the atomizers into the small and large diffusers of the carburetor. The fuel channel of the idle system is blocked by an electromagnetic shut-off valve after the ignition is turned off. The normal state of the energized valve is open. The idle system draws fuel from the emulsion well of the first chamber. The fuel passes through the idle jet, structurally integrated with the electromagnetic shut-off valve, and mixes with air entering through the idle air jet and the openings of the transition system of the first chamber. The resulting emulsion is fed through two channels (one has a calibrated hole - a jet, and the other has an adjusting hole, otherwise called a quality screw) to the hole blocked by the needle of the quantity screw, where it is additionally mixed with air and then enters the inlet pipeline through the emulsion hole. The composition of the mixture is regulated by the quality screw. When the throttle valves are partially opened (before the main metering system is switched on), the air-fuel mixture enters the chambers through vias - two in each chamber. The econostat provides fuel supply directly from the float chamber to the econostat atomizer, which is located in the diffuser of the second chamber. The econostat is switched on at maximum power modes, further enriching the working mixture. Accelerator pump - diaphragm type, mechanically driven from the axis of the throttle valve of the first chamber. With a sharp opening of the damper, a portion of fuel is injected through the sprayer into the first chamber of the carburetor, enriching the mixture. The pump is equipped with ball valves. One valve - a check valve - is located in the channel connecting the float chamber with the cavity of the accelerator pump. It opens when the pump cavity is filled with fuel and closes when fuel is injected by the diaphragm. Another valve is located in the atomizer. It opens under the pressure of the injected fuel and closes under the weight of the ball as soon as the fuel supply stops. Excess fuel during injection flows through the bypass jet back into the float chamber. The performance of the pump depends on the profile of the cam, the diameter of the hole in the bypass jet, the profile and length of the adjusting needle in the channel of the bypass jet. The accelerator pump is not subject to adjustment during operation. The starter consists of the choke, choke lever, telescopic link, throttle link, diaphragm mechanism and throttle control actuator. When the drive handle (“suction”) is pulled out from the driver’s seat, the air damper closes, and the throttle valve of the first chamber opens slightly by 0.7–0.8 mm (starting clearance). At the first flashes in the cylinders, the vacuum behind the throttle valve is transmitted to the diaphragm, which opens the air damper through the rod and rod. The maximum opening of the damper is adjusted by the diaphragm stop screw located under the plug screw.

Calibration data for the carburetor DAAZ 2107-1107010-20

Options | First camera | Second chamber |

Diameters, mm: |

||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

| ||

Delivery of the accelerating pump for 10 full strokes, cm 3 | ||

Calibration number of the mixture sprayer | ||

Emulsion tube calibration number | ||

Float distance from carburetor cover with gasket, mm | ||

Gaps at the dampers for adjusting the starting device, mm: |

||

| ||

| ||

Classic "six"

The VAZ 2106 car was produced by the Volga Automobile Concern for 30 years, from 1976 to 2006. Until the end of the 90s of the 20th century, it was equipped with gasoline carburetor engines with a displacement of 1100 to 1600 cm³. The fuel system of the VAZ 2106 car included several different carburetors, the most common of which was DAAZ 2107 OZONE.

It provided the greatest efficiency when driving in all modes. But this unit also had disadvantages, for example, low reliability and a strange way to open the second chamber. The main malfunctions of this device are associated with clogging of the jet channels due to the use of low-quality gasoline and the untimely replacement of the air filter cleaning element, ruptured diaphragms and broken springs.

You can troubleshoot the VAZ 2106 carburetor yourself, but for this you need to strictly follow the instructions. Otherwise, instead of solving existing problems, you will create a lot of new ones.

Types of carburetors for VAZ

Standard DAAZ 2106-1107010

On the conveyor for VAZ 2106 cars, 5 types of carburetors were installed:

- DAAZ 2103-1107010 "WEBER". It was mounted together with 1.5-liter engines on cars manufactured before 1980.

- DAAZ 2106-1107010. It was installed together with 1.6-liter engines on cars manufactured before 1980.

- DAAZ 2107-1107010-20 "OZONE". It was installed with 1.5- and 1.6-liter engines on cars manufactured from 1980 to 1991.

- DAAZ 2105-1107010-20 "OZONE". It was installed together with 1.1- and 1.3-liter power units on cars manufactured from 1980 to 1991.

- DAAZ 21053-1107010 SOLEX. It was put on all cars produced since the collapse of the USSR and until the end of the 90s.

The first 2 types of carburetors can be distinguished from the rest of the units by the absence of a pipe on which the hose of the ignition timing vacuum corrector is put on. This thin yellow or black hose goes from the VAZ 2106 carburetor to the distributor.

You can distinguish "OZONE" from other types of devices by the presence of a "flying saucer" - a pneumatic drive for opening the second chamber. If there is a “flying saucer”, but there is no nozzle for the vacuum corrector hose, then this is a DAAZ 2107-1107010-10 carburetor. This unit is quite rare, it was installed only at service stations to replace the first 2 types of devices after their breakdown.

The most common breakdowns

Since the carburetors of the WEBER and SOLEX families were completely copied from foreign analogues, their reliability is not satisfactory. It is enough to clean and adjust these units every 60,000 kilometers, and there will be no problems with fuel supply to the engines of your cars.

However, the most common are devices of the OZONE family. They need to be cleaned and adjusted twice as often. In addition, they have a lot of different diaphragms that break every now and then. The most frequent breakdowns of these units are the incomplete opening of the second chamber, as well as malfunctions of the accelerator pump.

Carburetor Drive Adjustment

Symptoms of the most common breakdowns.

- Clapping when you press the accelerator pedal, as if something is shooting into the carburetor.

- Similar pops, but now fires at the silencer.

- The idle speed is either too high or too low (floating).

- The car thinks for a long time when driving on the highway. When you press the gas pedal to the stop does not accelerate at all or accelerates too slowly.

- When shifting into 2nd or 3rd gear, pressing the accelerator pedal, the car first slows down, and then makes a jerk forward with a sharp set of revolutions.

The malfunctions indicated in points 1 and 2 occur due to detonation - microexplosions of the combustible mixture. If detonation occurs in the intake manifold, then the fuel mixture is too lean, too much air and not enough gasoline. If detonation is in the muffler, it turns out that the fuel mixture is too rich, there is not enough air in it.

The problem of detonation may be associated with a violation of the angle of installation of the ignition timing. In any case, you should first try to eliminate knocking by adjusting the carburetor. It helps 90% of the time.

The symptom described in paragraph 3 indicates the need for idle adjustment. The situation indicated in paragraph 4 informs that the drive 2 of the camera is faulty. Eliminated by replacing broken parts. The symptom described in paragraph 5 indicates a breakdown of the accelerator pump - a diaphragm or spring needs to be replaced.

The regular carburetor VAZ 2106 is a product under the item number DAAZ 2107-1107010-20, which received the code name "Ozone". This is a two-chamber emulsion-type fuel equipment that performs the functions of distributing and metered fuel supply to the power plant.

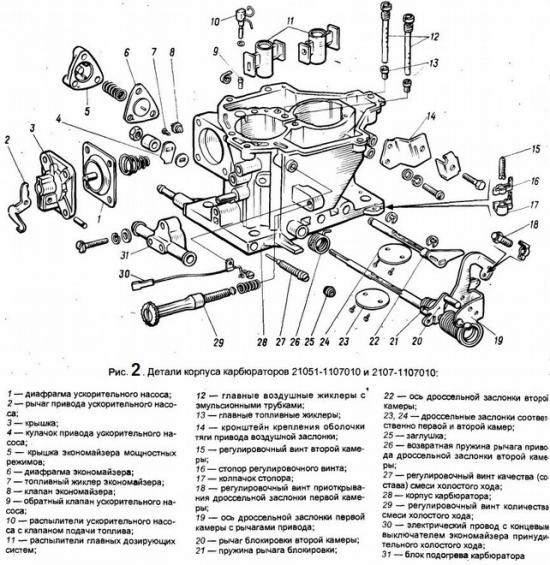

Carburetor device

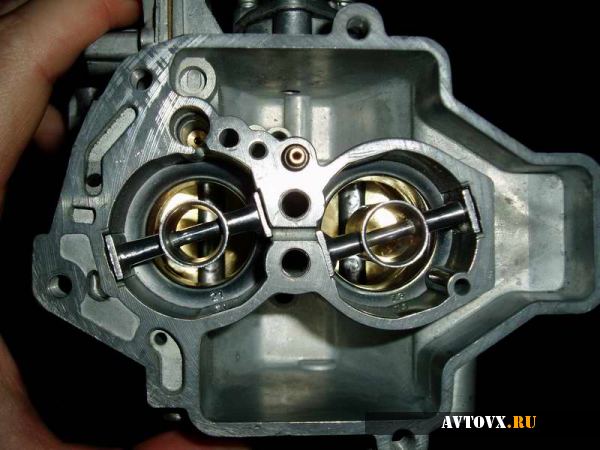

The general arrangement of the VAZ 2106 carburetor assumes the presence of:

- 2 chambers, and in the main one there is a diaphragm-type accelerator pump with an element for spraying the fuel-air mixture, and in the additional one - a mixture enrichment component;

- chambers with a float that determines the fuel level;

- a complex with a spool for the removal of gases from the crankcase of the power plant;

- shut-off valve of the electromagnetic principle of operation;

- pneumatic actuator of the throttle damper of the additional chamber;

- 2 main dosing complexes;

- idle speed control system.

As an alternative to Ozone, a Solex carburetor is offered, which, in our opinion, has been somewhat modernized. A device such as a Solex carburetor is more stable and reliable during continuous operation of the vehicle. This component fuel system shows better performance, dynamic performance and lower fuel consumption, which is very important.

Such advantages are provided by the functionality of the main dispenser, which is configured to form less rich fuel mixtures. The creation of more enriched fuel mixtures occurs due to a device such as an economizer. Therefore, it is rather difficult to determine which carburetor is better in the VAZ 2106, and it is better to leave the solution to the issue for motorist forums.

How does a stock carburetor work?

The VAZ 2106 factory carburetor operates in the following mode: fuel is supplied to the distribution system of the product, which passes through a mesh filter and a needle-type valve connected through a cable to a float device. This makes it possible to regulate the required level of gasoline. Through the float device, the fuel, passing through the carburetor jets, enters the pipelines to create an emulsion, where it forms a mixture with the air flow entering through the VAZ 2106 carburetor jets for air. Further, the fuel-air mass, passing through a spray-type system, reaches diffuser devices of small and large diameters.

Then the emulsion mass is transferred to the channel, the diameter of which is controlled by moving the needle of the mixture quality screw, in which the final enrichment with oxygen is carried out before being fed into the start-up system. The schematic diagram of the VAZ 2106 carburetor is below.

Here you can also see the device of the carburetor, which is a very complex mechanical-electronic product. The main design feature of the VAZ 2106 carburetor is that this device is a combination of 2 separate and unrelated devices that operate independently of each other.

One of them serves the operation of such a component of the product as an idle VAZ 2106 carburetor, and the device includes a system of valves of a vacuum and electro-vacuum principle of operation, equipped with carburetor jets for fuel and air. Another mechanism is 2 fuel chambers, which start after the throttle valve opens (after pressing the accelerator pedal).

Although the systems are fairly autonomous complexes, their interaction in creating fuel mixture significantly affects the level of fuel in the float chamber. A change in the fuel level indicator affects the functionality of the product, because. the adjustment parameters of the mechanism are lost. So, idling loses its adjusting value, which leads to incorrect operation of the power plant.

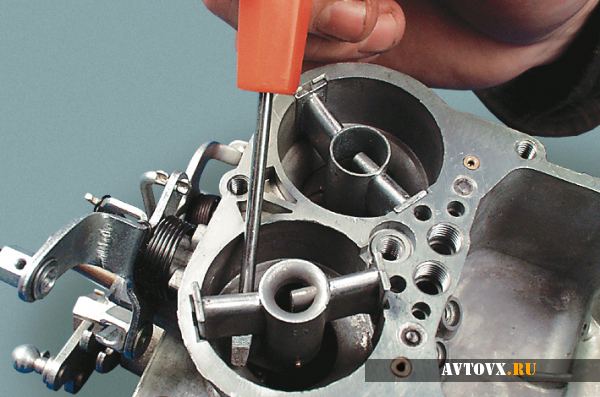

Separate elements of repair of the "six" carburetor

Qualified carburetor repair is carried out in specialized repair shops and car service stations with professional stands. However, individual repair work can be done with your own hands, having elementary skills in plumbing.

So, a number of malfunctions in the functionality of the product consist in clogging of fuel lines and small channels of small caliber carburetor jets, incl. and the presence of tar deposits in them from the composition of the fuel. This can be eliminated by washing the calibrated components and the internal planes of the product with acetone or its analogues and purging with a compressor at a pressure of about 4 kgf.

The idling system is most often subject to adjustment work and is carried out, as a rule, after passing 8-10 thousand km. This type of work is carried out by setting the positions of 2 bolts, the composition of the fuel mixture depends on the position of one of which, and its volumetric value depends on the second. Requirements for the start of adjustment: engine temperature - 85-90 ° C, antifreeze - 90-95 ° C, cylinder head valve clearances adjusted, throttle valve in the closed state, ignition timing determined according to the standard.

Progress:

- The frequency value of the rotation of the crankshaft by the wine of the amount of the fuel mixture is set within the range of 0.8-1 thousand rpm.

- The percentage concentration of CO in the exhaust gases with the fuel mixture quality screw is set within the range of 0.5-1.2 cents.

- We regenerate the rotational speed value, which was knocked down when setting the level of carbon monoxide, within the limits of 0.8-1 thousand rpm.

- It is also possible to restore the CO concentration parameters in this case.

- Next, you need to sharply press the accelerator pedal, followed by its release from effort. The following picture should be observed: the increase in frequency occurs without interruption, its decrease leads to the fact that the power plant operates at low crankshaft speeds. If the engine stalls, then it will be necessary to re-adjust the frequency indicator of rotation of the crankshaft of the engine with a value of 0.8-1 thousand rpm.

Another common defect is such an indicator that the VAZ 2106 carburetor does not start for the following reasons:

- in case of clogged fuel lines, it is required to pump them with a compressor unit, and the gas tank should be washed and steamed;

- if the fuel pump or the mesh filter components of the carburetor are clogged, they must be cleaned, and in case of defects, they must be replaced.

There is also such a defect in the “six” fuel system when it shoots at the VAZ 2106 carburetor when the engine is started. If at the same time the carburetor and the gasoline pump are checked, which are functioning correctly, then the VAZ 2106 spark plugs are “to blame” for this malfunction, the glowing element of which is dirty or oily. They need to be cleaned, degreased, and, if necessary, replaced.

Sometimes, as an element of upgrading the "six", a turbine is used on a carburetor, which, with the correct installation of this device, increases the power of the power plant. It is very important to correctly install and connect this device to improve the dynamic performance of the car.

Any VAZ 2106 carburetor, the price of which will differ according to the brand of the manufacturer, is mounted on a vehicle with basic knowledge of plumbing. Therefore, the installation of the carburetor is carried out by motorists without problems, it is much more difficult to make the correct adjustments to this product.

In extreme cases, if the old spare part does not meet environmental requirements, allows increased fuel consumption, does not keep idle and cannot be repaired, the carburetor must be replaced with a new product, followed by adjustment.

The VAZ 2106 car is an example of classic automotive European design and design solutions of the mid-twentieth century. Like everything in this car, the engine, gearbox, and clutch have become familiar to a huge army of fans of the classic Zhiguli. However, such complex devices and assemblies as a carburetor require more detailed study, which we will do today.

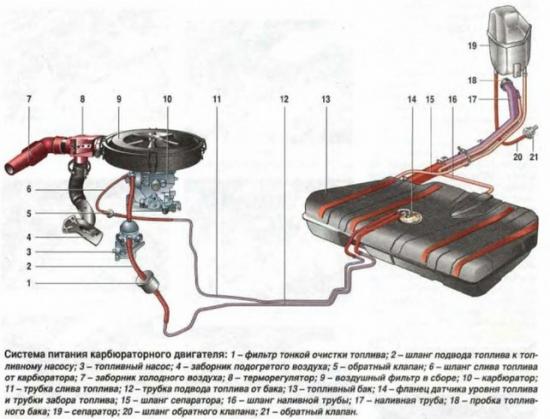

Features of the power supply system VAZ 2106

The power supply system of the VAZ 2106 car is arranged according to the standard scheme, which was used on all carbureted cars of the last century. Fuel from the tank is supplied through a copper gas line to the engine compartment. The pressure required to supply the fuel creates a membrane type, which is driven by an eccentric cam. The fuel is cleaned of large fractions by a strainer in the gas tank, as well as in, however, as practice has shown, this is completely insufficient for the smooth operation of the carburetor.

Therefore, almost all owners of classic Zhiguli install additional fine filters directly at the carburetor inlet. These filters are usually made of transparent plastic, which allows you to control the degree of contamination of the mesh or pleated filter element.

Model range of carburetors for VAZ 2106

Carburettors of different models were installed on the VAZ 2106. As a rule, cars from 1974 to 1976 were equipped with a carburetor from the DAAZ plant, model 2103-1107010-01. This is a licensed copy of a Weber carburetor. Structurally, the carburetor was no different from the carburetor of the VAZ 2101 car, but had slightly different calibration parameters, which we listed in the table.

Later, when a vacuum ignition advance corrector began to be used in the design of the ignition system, the design of the carburetor was changed. The factory index of the Ozone carburetor is 2107-1107010-20. Cars that were equipped with an old-style distributor, without a vacuum ignition timing corrector, were equipped with exactly the same carburetor, but without a tube that connected the intake manifold and the vacuum adjustment mechanism on the distributor. The model of such a carburetor is 2107-1107010-10.

The device of the VAZ 2106 carburetor is shown on the branded Togliatti poster, which we posted on the page. There is nothing daunting in the device of the carburetor, but the work and, most importantly, the adjustments of some of the main parameters of this carburetor should be said separately. The main systems of the Ozone carburetor:

- autonomous system XX;

- pneumodiaphragm starter;

- accelerator pump, also pneumodiaphragmatic type;

- economizer with pneumatic drive;

- transitional systems that ensure the smooth operation of the secondary chamber;

- crankcase ventilation system.

Despite the rather primitive device, the carburetor showed itself perfectly in all engine operating modes. However, major systems require adjustment to achieve optimum power, economy and engine dynamics.

Working principle and maintenance

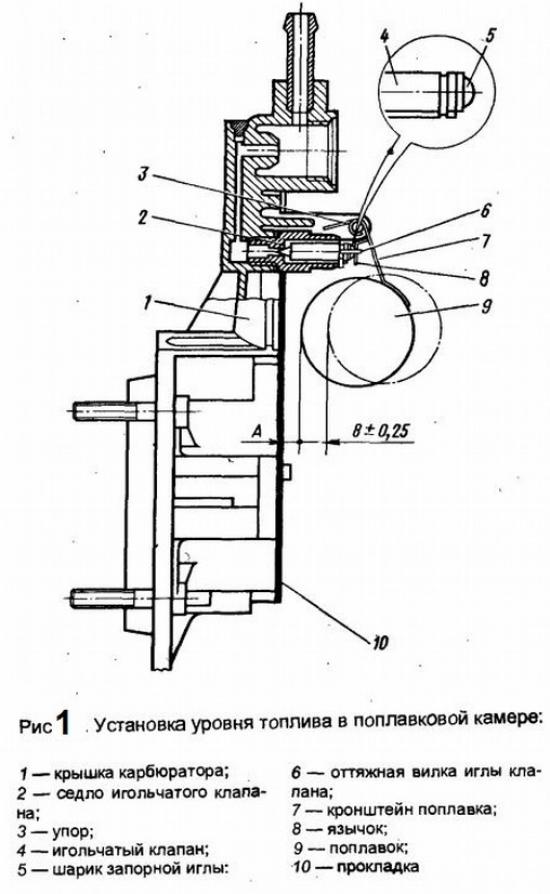

One of the main adjustments of the Ozone carburetor is the adjustment of the fuel level in the float chamber. The level affects both the economic performance of the engine and the accelerating dynamics, start-up and operation at high speeds. If the fuel level in the float chamber is insufficient, the engine will run on a lean mixture, which will affect the speed stability in transient conditions, and the engine will not be able to develop nameplate power, there will not be enough fuel.

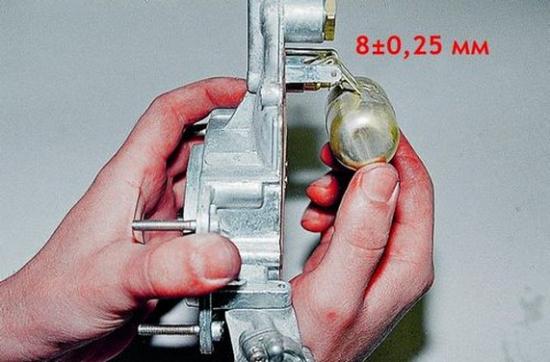

To determine the correct level in the float chamber, it is necessary to dismantle the air filter with the housing and the top cover of the carburetor. The passport gap between the float and the plane of the carburetor cover gasket should be no more than 6.5 mm. The clearance is adjusted by bending back the float tongue (A), which should just touch the needle valve ball during measurement.

In this case, it is necessary to check the tightness of the valve. To do this, it is enough to create a vacuum in the tube, put on the fitting, either with your mouth or with a pear. If the tightness of the valve seat is broken, the valve needle itself must be replaced together with the seat. They are sold as a kit or separately. If the tightness of the valve is good, it remains only to check the free play of the float. It must be at least 8.5 mm.

Having mastered the basic methods of adjusting the VAZ 2106 carburetor and its design, you can achieve optimal fuel consumption, satisfactory acceleration dynamics and optimal engine power. And when working with Ozone carburetors, it is enough to study the layout and arrangement of the assembly, then adjusting, cleaning and replacing jets, gaskets and diaphragms will not be difficult. Good luck on the roads, stable engine operation and high-quality fuel!