If you actively use small-sized agricultural machinery, like walk-behind tractors, you probably encountered some problems in their work. One of the most common questions among owners of this type of equipment is “why does the walk-behind tractor stall?”.

In the vast majority of cases, this is due to engine malfunctions, which can be completely eliminated on your own without contacting specialized workshops.

1 Components of a walk-behind tractor and their functions

With a compact size, the walk-behind tractor is a rather complex mechanism, for diagnosing malfunctions of which you must first understand what the function of its main components is.

The classic walk-behind tractor consists of the following systems and elements:

- fuel system, which includes a carburetor, a fuel tank equipped with a crane, a supply hose and an air filter;

- starter manual or electric (in professional models), designed to spin the main shaft (this function is performed by the starter cord);

- cooling system, driven by the rotation of the crankshaft and providing forcing the air flow by the flywheel impeller;

- ignition system, responsible for the formation of a spark;

- gas distribution system, serving fuel mixture into the engine cylinders and ensuring the release of gaseous waste.

1.1 Types of motor block engine breakdowns and methods for diagnosing them

2 Do-it-yourself repair of cultivators

The most affordable and popular models, which are preferred by summer residents and farmers, are: walk-behind tractor MB, MB 1, Agro, Mole, Zirka and Bison. Repair of the Zubr walk-behind tractor, like all other listed models, can be easily done by hand by replacing certain structural elements by buying them (including the old model) at specialized disassemblies.

However, we will consider the most common technologies for self-diagnosis and troubleshooting of key elements in their design.

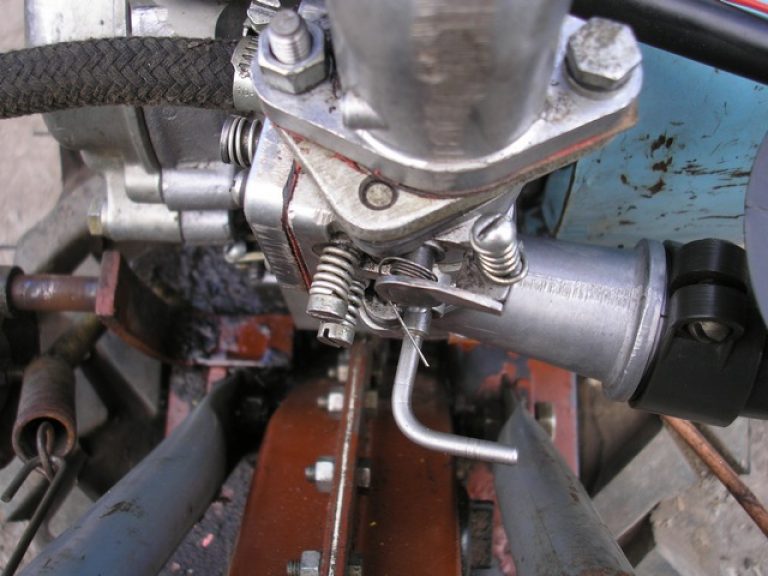

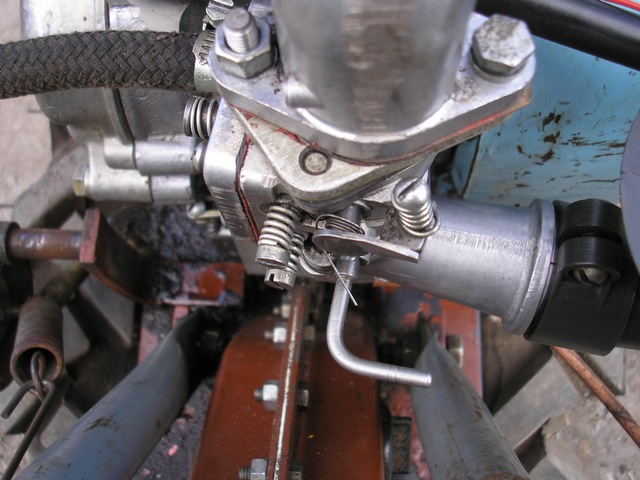

2.1 Repair of the motoblock carburetor

Restoring the function of a carburetor is made easy with the help of its competent cleaning of blockages. To eliminate contamination, the unit is disassembled, cleaned in accordance with the manufacturer's recommendations and re-adjusted. The algorithm of actions is in the instruction manual for walk-behind tractors.

You can adjust the carburetor by adjusting the functioning parameters of the float, which is located in a partially closed chamber.

All manipulations come down to restoring the uniformity of its immersion by eliminating the deformation of the bracket with which it is attached to the piston system.

Adjustment can be made with the needle valve closed or open. In both cases, the removal of the deformation of the bracket is carried out manually or using a screwdriver, all actions must be precisely directed.

Simultaneously with the repair or diagnosis of the condition of the carburetor, it is also recommended to adjust the valves on the walk-behind tractor. The procedure involves checking the tightness of each valve to restore optimal valve clearance. Adjusting the valves of the walk-behind tractor allows you to restore its functions, with the exception of serious breakdowns in the carburetor or other systems of the unit.

2.2 Overhaul of a walk-behind tractor (video)

2.3 Fuel pump repair

The high-pressure fuel pump, or high-pressure fuel pump, performs one of the key functions in the operation of a walk-behind tractor - at a certain point in the cycle it supplies metered fuel to the engine cylinders.

Signs of a pump failure are:

- violations in the supply of fuel to the engine injectors;

- fuel leakage as a result of mechanical wear;

- atypical noises and sounds during operation;

- failure of the main settings.

A properly adjusted fuel pump ensures the correct operation of the engine and other walk-behind tractor systems. The design of this element is quite complicated, so we do not recommend repairing it yourself.

2.4 Transmission dysfunctions

As you know, crankshaft-based mechanisms are set in motion by a transmission, which a serviceable belt on a walk-behind tractor is capable of providing. As practice shows, this is one of the most vulnerable and subject to mechanical wear elements in the design of a walk-behind tractor.

It is he who provides:

- timely transmission of torque from the crankshaft of the motor to the gear shaft;

- adjusting the load on the engine during gear shifting;

- the ability of equipment to move from a place and stop without necessarily stopping the operation of the motor.

If you notice atypical behavior of the walk-behind tractor in one of the cases listed above, we recommend that you carefully examine the condition of the belt and check its tension level. As practice shows, repairing a tensioner for a walk-behind tractor with your own hands is quite simple by welding a part of a similar size and configuration from a metal corner.

Another indicator of problems with the transmission is a violation of the speed reduction parameters to the operating rate, the adjustment of which is provided by the creeper, or gearbox. It is very difficult to make this element for a motor cultivator on your own, since in terms of design it is similar to a gearbox. You can buy it inexpensively in almost any city, and some models, for example, the MB motoblock gearbox, can be used to repair other models of motor cultivators.

Motoblock Mole is a means of small-scale mechanization, designed directly to work with the ground. Its great popularity in our country is due to the fact that, at its low cost, it shows quite good technical characteristics.

However, in order for this walk-behind tractor to continue to work correctly, it is necessary to periodically perform its maintenance.

These measures can significantly extend the operational life of the unit, without losing its working qualities.

One such service is carburetor adjustment, which must be carried out immediately after the end of the first season of work.

Motoblock Mole is a fairly standard design. without the use of frills. This model of a walk-behind tractor began to be produced in 1983 in Moscow, but then the production of this unit expanded, so they were also produced in Omsk.

They were equipped with factory engines, the power of which did not exceed 2.6 hp. It is attached, like the gearbox, to the frame with ordinary bolts. The declared power was not always enough, so many Mole owners adapted to some alterations, changing the factory motor to more powerful models.

In general, the Mole motoblock device looks like this:

- Frame structure on which the internal combustion engine and gearbox are located.

- The control handles on which the clutch is located, as well as the engine speed controller.

- Wheel base, allowing you to freely move the unit from place to place. During operation, these transport wheels are removed.

- Soil cutters that are put on the output shafts of the gearbox.

For more details about the Mole walk-behind tractor, see the video:

As we see the design is very simple, which allows you to make repairs yourself. And you may have to do this, because the factory engine does not always work in a stable mode.

The principle of operation of the Mole walk-behind tractor is as follows. The rotational moment is transmitted to the gearbox, and then to its two output shafts through the V-belt. When the clutch is pressed, the belt is tensioned, driving the gearbox shaft.

This gearbox shaft, on which the cutting elements (soil cutters) are located, rotates around its axis, cutting off the soil crust, at the same time crushing and mixing it. Such translational movements carry out the movement of the walk-behind tractor on the surface of the earth.

The set includes four soil cutters, which need to be arranged in pairs, on each side of the shaft. By the way, it is possible to install six cutting elements at once, which improves the quality of tillage.

The scope of this and other walk-behind tractors, such as, can be significantly expanded by attaching additional attachments to it. It is attached to the unit through a special bracket located behind the walk-behind tractor.

You will have to purchase such equipment separately, but thanks to it, an expanded front of work opens up:

- transportation of goods of various weights;

- processing of inter-row spaces of beds;

- hilling and weeding beds;

- harvesting hay for livestock;

- planting and digging up potato tubers;

- using a pump, you can water the beds, etc.

In other words, with the help of the Mole walk-behind tractor, virtually the entire range of agricultural work can be carried out. This circumstance makes it an indispensable assistant for a rural resident who uses his garden to the fullest.

Adjustment

Many people ask themselves - how to adjust the carburetor installed on the Mole walk-behind tractor? Many note that it is this working node that causes the most problems. The thing is that on the Mole a Soviet K60-V carburetor was also installed, which is used in the construction of mopeds.

Before describing the likely problems with it, you need to consider how to adjust this carburetor, which will help to avoid these same problems. So, our actions will be as follows:

- To adjust the fuel level of the carburetor, we need to remove the float chamber of the Mole walk-behind tractor.

- After that, turn the carburetor over so that the float is at the top. Then we bend the tongue until the distance H is exactly about 15-17 mm.

- In the design of this carburetor There are two adjustment screws. One regulates the throttle lift, and the second controls the quality of the mixture used. The design is made in such a way that when the second adjusting screw is screwed in, the mixture is enriched and vice versa.

- First, the engine needs to warm up a little, and then start idling control. By the way, at the initial stage, you need to adjust the ignition.

- We adjust the position of the screw responsible for the quality of the mixture. To do this, it is necessary to screw it 1 or 1.5 turns counterclockwise until it stops.

- At this time, the throttle screw will normalize the stable operation of the engine. Then, with the quality screw, we achieve an increase in the number of revolutions.

If everything is done correctly, then the engine will normally respond to the opening of the gas, without the appearance of dips. In addition, the rotational speed will remain unchanged, regardless of the degree of warming up.

Motoblock carburetor produced back in Soviet times. Despite the fact that the Soviet industry was famous for its high level of performance and reliability, nevertheless this carburetor had several flaws. To understand them, you first need to make a complete analysis of it into its components:

- Remove the cover by unscrewing the bolt on it. Under it, we find a gasket made of gasoline-resistant material, as well as a spring that needs to be pulled out.

- We take out the shutter, located in the same place, under the cover.

- On the reverse side is a float chamber, which also needs to be unscrewed. We remove the lining.

- Then you need to remove the float by removing the pin from the corresponding hole. Under the float finds a special needle, which also needs to be removed. On it we find a small elastic band, which in no case should be lost, so we carry out all the manipulations very carefully.

- We unscrew the fitting under which the gasoline filter is located.

- Then you need to remove the jet. After that, we need to pull out absolutely all the "insides" that are in the carburetor body.

Such disassembly is necessary, because we get access to the internal content, which is considered the most problematic.

The most common drawback of such carburetors is the adjusting screw, which is responsible for the quality of the mixture.

Disassembly

Disassembly In other words, we turn this screw, but the mixture does not change, it remains constantly unchanged.

To change this, you need to make some repairs to the carburetor located inside the Mole walk-behind tractor. The main cause of problems with mixture adjustment is one circumstance. The fact is that inside the carburetor there is a special channel that runs to the tube located in the center of the carburetor.

The T-70S tractor is a multifunctional unit for a wide range of activities. By clicking on, get acquainted with the advantages and features of the T-70 tractor.

Bulldozer - an earth-moving machine on a caterpillar or wheel drive, belonging to the class of special equipment. - the largest in the world of automotive special equipment.

The market of our country presents the products of a large number of manufacturers of snowplows with a worldwide reputation. all about the legendary German snow blower Huter.

In this pipe, in theory, there should be a through hole connecting this same channel. The problem is that on some factory units this pipe is placed obliquely, which leads to the fact that the channel and the hole on the pipe do not match.

There are cases that this hole is completely absent on the pipe, or it is of insufficient diameter. To make repairs, we need to perform several sequential steps:

- Loosen both adjustment screws. Please note that the screws have different tapers - the mixture quality screw has a larger taper.

- To pull out the pipe that is inside, we need to slightly heat the part of it that is outside. To do this, you can use a small fire on a gas stove, or heat it with a regular lighter.

- We heat until we can hold the body in our hands. After that, we put the pin into the hole where the cover bolt was located.

- Using a hammer, carefully hit the inserted stud until the pipe pops out.

- As practice shows, the hole is drilled on only one side of the pipe, those. it is not transparent. We need to make a symmetrical hole on the other side of this tube, or modify the one that is.

- If there is a second hole, but it is smaller in diameter than the first, then we need to grind it a little. To do this, we use a regular round needle file, bore the edges of the hole.

- Then we install the tube in its original place. This must be done in such a way that the through hole on it and the hole on the channel exactly match.

- Before inserting the tube into place, you need to heat up the carburetor body a little again, so that she enters without problems in her place.

- We insert the tube into place and with the help of the same pin with which we pushed the pipe out, we insert it into place. We knock lightly so that the pipe does not go far inward - on the reverse side we should see a hole located just above the through one, which should coincide with the channel.

- You need to make sure that the hole is exactly in the center.

- We take a dense wire and insert it into the opening of the channel. If everything is done correctly, then the wire should freely pass further, through the through hole on the pipe, and exit it in the continuation of the carburetor channel.

- If the wire rests, then you need to knock a little more on the hairpin, pushing the pipe a little further.

- Next you need reassemble the carburetor in reverse order.

That's the whole process of the necessary changes in the design of the carburetor. Thanks to them, the adjusting screw fully fulfills its duties of changing the quality, which, in fact, was required of it.

Conclusion

Application of motoblock Mole widely used in many regions of our country. This is no coincidence, because through fairly simple alterations, you can get a fairly powerful unit out of it, comparable to more expensive models.

But even without that, even with the factory version of the engine, it is able to cope with most of the tasks assigned to it.

However, in order to achieve this, it is necessary to periodically adjust the main working units of the device.

You can find out about this frequency in the operating instructions that come with the walk-behind tractor. It contains all the detailed information about how to clearly configure, as well as when to do it.

Motoblocks today have become a very popular technique among farmers, summer residents and rural residents. Therefore, questions about their repair and correct operation do not get tired of leaving the Internet pages. Since sooner or later the equipment fails, for various reasons, that is, the need to either contact a service center, or solve the problem on your own. Many, of course, begin to repair at home, which is much more economical than contacting specialists. But you need to remember that you should know how to do it, or at least have instructions at hand.

Today we will talk about a frequent malfunction of the Neva walk-behind tractors, namely, we will provide detailed instructions for adjusting the carburetor of the mb-1 and mb-2 walk-behind tractors.

Everyone knows that the carburetor is a very important part in the walk-behind tractor system. It is on him that the efficiency and success of the operation of the engine and other systems depends. So, we will tell you step-by-step instructions for adjusting the carburetor for the Neva mb 2 and mb-1 walk-behind tractor.

Details of adjusting the carburetor of Neva walk-behind tractors

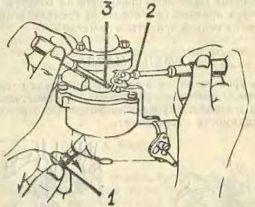

To repair this device, you can safely use these conditional instructions in the picture and the tips below:

To repair this device, you can safely use these conditional instructions in the picture and the tips below: - Screw in the full throttle screw No. 1 and the idle screw No. 2 to the end.

- We unscrew the same 2 screws approximately 1 - 1.5 turns.

- We start and warm up the engine.

- Now we set the lever that controls the throttle until the engine is turned off (that is, until the moment when it corresponds to the lowest speed).

- We set the minimum stable idle speed with screw No. 3.

- Using screw No. 2, you need to set the idle speed to the maximum level.

- We correct the minimum stable idle speed with screw No. 3.

- We do points 6 and 7 until we get an uninterrupted and stable idling engine at minimum speed.

- If, nevertheless, interruptions in work are present, then screw No. 1 must be unscrewed and screwed back. We perform this operation until the normal operation of the motor resumes.

We adjust the KMB-5 carburetor on the Neva walk-behind tractor

![]() The provided scheme will allow you to easily and simply adjust the carburetor of the KMB-5 model to the Neva walk-behind tractors on your own. This guide is very clear and simple. By following each step clearly, you can easily resume the operation of this device.

The provided scheme will allow you to easily and simply adjust the carburetor of the KMB-5 model to the Neva walk-behind tractors on your own. This guide is very clear and simple. By following each step clearly, you can easily resume the operation of this device.

In the modern world, a walk-behind tractor has become very popular among summer residents. This is a fairly convenient device with which you can cultivate the soil without effort and a lot of time. Accordingly, the question of how the carburetor is adjusted for the Neva walk-behind tractor began to appear on pages on the World Wide Web more and more often. This is due to the fact that, like any equipment, this device can break down, and not only adjustment, but also major repairs will be required.

A large number of people immediately begin to experiment and solve the problem of breakdown on their own. Repair at home will, of course, be cheaper, but for this you need to have a certain amount of knowledge, tools, or have detailed instructions. Next, you will learn about the possible problems that a carburetor on a walk-behind tractor has, and how to fix them.

The carburetor is the distribution element of the system, which sends fuel to the combustion chamber. The carburetor for the Neva MB 2 walk-behind tractor is rotary and plunger. Rotary is used in small engines, and plunger in large and powerful units.

In order to adjust the carburetor of the Neva walk-behind tractor, you must follow the following instructions:

- first we unscrew the full throttle screws, turn them off a few turns;

- we start the unit and warm it up for a while;

- then, to adjust the carburetor, it is necessary to set the clamping lever to the engine off position;

- set the idle speed, do these actions until we reach the engine at minimum speed.

If you regularly load the walk-behind tractor, the valve clearance may change. The cause of this problem is the wear of the part. If the gap is large enough, then you can hear strange tapping or just noises. Due to the incorrect distance of the valves, the power of the device may decrease and the unit will malfunction. In this case, adjusting the carburetor of the walk-behind tractor is simply necessary as soon as noises are heard. In order to correctly adjust, wait until the engine cools down.

Attention! In order for the device to serve for a long period of time, be sure to remember the following rules:

Attention! In order for the device to serve for a long period of time, be sure to remember the following rules:

- check the unit regularly;

- change the oil regularly;

- adhere to all requirements for the operation of the walk-behind tractor as much as possible.

These are the basic steps by which you can keep your technique in working shape.

Device Care

There are situations when adjusting the carburetor no longer helps, repair or replacement of the part may be required.

The air damper may not close tightly, in order to correct this breakdown, it will be necessary to control the operation of the drive. It is also necessary to regularly inspect the walk-behind tractor itself and take care of every detail in order to ensure regular fuel supply and high-quality operation of the device. In addition to the need to regulate idling, it is also necessary to clean the carburetor and, if necessary, replace worn parts with new ones. To make the part less contaminated, you can use special filters, which should be changed periodically.

The air damper may not close tightly, in order to correct this breakdown, it will be necessary to control the operation of the drive. It is also necessary to regularly inspect the walk-behind tractor itself and take care of every detail in order to ensure regular fuel supply and high-quality operation of the device. In addition to the need to regulate idling, it is also necessary to clean the carburetor and, if necessary, replace worn parts with new ones. To make the part less contaminated, you can use special filters, which should be changed periodically.

In addition, to avoid breakdowns, purchase only high-quality fuel. Thus, you can significantly extend the life of the carburetor.