When choosing a disc for an angle grinder (angle grinder), you must first adhere to the diameter established for a particular model.

In the article we will talk about:

And this is really a very important point, because often, in order to increase the depth of cut or the area of the surface to be treated, some "craftsmen" remove the protective cover and set a circle of superior dimensions.

Firstly, because of this, the tool itself fails much faster (the gearbox breaks), and secondly, quite severe injuries occur. The fact is that each disk for an angle grinder has restrictions on maximum revolutions or, in other words, on rotation speed.

The wider the diameter of the circle, the lower the speed should be. That is why large discs at high speeds very often simply break, and given that there is no protective cover, the consequences can be the most deplorable.

What are the discs for grinders in diameter

In total there are 5 main modifications:

- ∅ 115 mm

- ∅ 125 mm

- ∅ 150 mm

- ∅ 180 mm

- ∅ 230 mm

The most popular are grinders, and, accordingly, discs ∅ 125 and 230 mm. In everyday life, small models are most often used, while in professional work a more powerful and productive tool is used.

How to choose a disc for an angle grinder to work with various materials

The versatility of the grinder lies in the fact that it can not only cut almost any material, but also grind all kinds of surfaces or sharpen tools. The main thing is to choose the right disk. So what are the discs for the grinder? The main groups look like this:

- cutting

- cleaning (grinding)

- grinding (roughing)

In turn, in each group there are several varieties. Cutting discs are abrasive, diamond and wood. The former, as a rule, are intended for cutting metal, although there are also abrasive wheels for concrete.

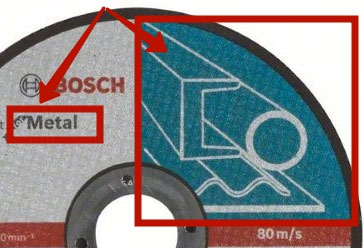

They differ in the components used in the production, and the buyer can distinguish them by the color on the information sticker ( for metal - blue, for concrete - green), according to the inscription ( metal - "Steel", concrete - "Concrete") or according to a schematic representation of a particular material.

Diamond cutting wheels are designed exclusively for stone, concrete or ceramic products. The most common question that home craftsmen have is which disc to cut tiles with a grinder? In general, for these purposes, circles with a continuous coating without segmentation, grooves and slots are recommended, since they leave a minimum of chips on the enamel.

However, they are used in conjunction with water cooling, that is, on special electric tile cutters with a continuous supply of water. For household purposes, you can use segmented discs, which are also suitable for red and sand-lime bricks, pavers, concrete, paving slabs, etc. It is not recommended to work continuously with any diamond wheels for more than 2 minutes, because, despite the cooling grooves, cuts and grooves around the entire circumference, they heat up very quickly when cut dry.

Another common question is how to cut thick rubber or a car tire? A grinder can also perform this operation, for example, with a diamond disc. But you need to do this outdoors, because when heated, the rubber emits a pungent odor and can even smoke.

You need to be very careful in the case of tires, as there is a metal court in the middle of the ramp. A diamond will certainly cut it, but small particles of metal can bounce off. In addition, rubber very often pinches the disc, so you need to open the edges during the cutting process.

There are special saw blades for cutting wood. This is the most dangerous kind of circles, because even with the slightest contact with hands or fingers, they leave severe injuries. They are recommended to be used only if the angle grinder is fixed to the workbench.

If this is not possible, you need to work as carefully as possible, in no case remove the protective cover, do not put pressure on the tool, do not make any sudden movements, be sure to wear a mask and tight-fitting fingers. It is better to choose discs for a grinder for a tree with a small tooth, since such circles are less likely to provoke a kickback effect.

What are sharpening and grinding wheels for grinders?

Grinding abrasive discs are of two types: flat and bowl-shaped. In the first case, circles are practically no different from edged counterparts. The difference lies only in their thickness, which is at least 5 mm or more.

Cup-shaped varieties are more convenient to use, as they allow you to cover more of the treated surface in one pass. Use such discs for grinders in order to clean welds or sharpen cutting tools.

Grinding or roughing wheels are of four types:

- Petal (emery) discs for grinders are mainly used when removing old paint or varnish, polishing wooden surfaces.

- In order to clean the surface from persistent contamination or rust, special wire nozzles are used.

- Diamond cup-shaped modifications are intended for polishing the stone.

- For polishing metal, disc nozzles made of rubber or plastic are ideal, to which a replaceable emery or abrasive mesh is attached.

Which side to put the disc on the grinder?

This question is the easiest to answer. The flat circle is placed with the marking out. Cup-shaped modifications can only be placed in a single position, so there is no error here.

By the way, professionals say that there is no difference which side to put the disc on the grinder. Their belief is based on the fact that on circles, even professional ones, there is no arrow pointer in which direction the rotation should take place. Therefore, the installation can be carried out by any party.

Video:

In order to work as a grinder specific type materials, you will need to choose not only the equipment itself, but also certain types of disks. The angle machine is designed to process or cut certain materials, depending on which the disc is selected. There is a classification of discs according to what canvases they are intended for: for wood, for concrete and ceramic tiles, for metal. In addition, there is also a polishing and grinding wheel.

Circles for the grinder on wood

What are Wood Cutting Discs? If a tree is a soft canvas, then this does not mean at all that it is not dangerous to work with it. It is worth noting that only a professional should be engaged in this process, even if a high-quality and suitable circle is installed.

A wood disc for a grinder happens:

- Whole;

- With soldering of high carbon steel, which is located on the peripheral part of the disc.

The first type of discs is considered not too strong, relative to the second, since the circle on which the soldering is present requires an additional cleaning procedure. They are more durable and strong.

It is important not to confuse such blades with those used on special machines called a circular saw, since these are two different equipment and the disks on them are completely different.

The disk on the grinder has a different configuration, the diameter is 125 mm and the seat is 22.2 mm. It is strongly discouraged to use a larger saw blade, as this can be extremely dangerous. To be more precise, during operation, the canvas will gradually heat up and expand, which will lead to the fact that the circle is pinched or bitten. As consequences, the disinhibition of the disk and literally tearing the equipment out of the hands of the master are noted. Tragedy cannot be avoided here, and therefore you should not violate the recommendations of experts regarding the operation of the product. Each circle has certain dimensions, and all product parameters are indicated on its coating or packaging. These include: the steel grade from which the teeth were soldered, for example, VK-15; the number of revolutions, which is indicated by the letter H; the diameter of the product and what size the landing opening has; number of teeth.

Discs for grinders for metal: what are

Most often, even a small grinder is used to work on metal, for example, on: sheets, pipes, corners and more. nozzle or cutting disc for metal is made of electrocorundum, the grade of which should be 13A and 15A, white corundum - 23A and 25A, black silicon carbide 53C and 55C, and green silicon carbide - 63C and 64 C. Each of these materials is present in such a product as a cutting metal disc. The binding of the material is carried out by means of formaldehyde resin and a filler called pyrite.

To make the circle more durable, reinforcement is carried out with a fiberglass mesh, due to which the disk rotates at a speed of 90 m / s, which sometimes exceeds the permissible speed level indicated on the angle grinder, depending on the type of equipment.

The reinforcing mesh does not fit on the entire canvas, but does not reach the upper edge a little. A thin type of nozzle has one mesh, and a thick one has two. For those who work as a grinder as an amateur, or in other words, not too often and only at home, a circle with a diameter of 125-230 mm is enough. They are able to withstand a speed of 80 m / s and have a bore diameter of 22.2 mm.

The manufacture of such discs is carried out using black and white electrocorundum and in two configurations:

- flat;

- Convex center.

The last type of product is used for making an angular cut next to the walls. A circle whose diameter exceeds 230 mm is used mainly in industry and on special machines to cut metal and sharpen chainsaws. The seats of such canvases vary between 32-100 mm. Regardless of which disc will cut, in particular large or small, you need to learn how to set and select it correctly. All information about the canvases is present on a paper sticker located on the surface of the disc. In particular, these are: the type of material from which the circle is made; level of admissible linear speed; product thickness; hardness and size of the seat; what type of connecting element was used in the manufacture; the presence or absence of a reinforcing mesh.

Grinding disc for grinder

Grinding wheels are no less popular than the previous two types.

Grinding discs are divided into:

- flat;

- Cup-shaped.

Flat ones resemble edged ones in appearance, but they have a thickness of more than 5 mm. Cup-shaped are used for grinding a large area, for cleaning seams remaining after welding. They also sharpen the tool.

A disc that can be used to grind the surface can be:

- Petal;

- Wire;

- Diamond;

- Poppet.

A petal or emery wheel is used to work with wood to eliminate old paintwork. If a roughing process is needed to remove rust, it is advisable to use a wire nozzle called a wire brush or cork brush. A disc for grinding metal on a grinder (M14) is a rubber nozzle with a side in the form of a plate. It changes during operation. sandpaper or grids. To work on stone, it is worth using a diamond abrasive wheel in a bowl shape. The grinding wheel is selected according to certain parameters: outer diameter, bore diameter, thickness, grit, segment type and allowable rotation speed.

How to remove a disc from a grinder

It may be necessary to remove and change the disc on the grinder for various reasons. For example, a disk has cracked or the protective cover on the device has broken. In this case, the equipment cannot be used.

So:

- Before unscrewing or spinning the disk on the grinder, it is required to disconnect the equipment from the network. There is a special lock button that stops the shaft from working.

- Next, a special wrench is used to unscrew the lock nut. If the nut is too tight when the disc is jammed, then a gas wrench can be used to unscrew it, preheated with a cutter and then cooled quickly. The rest of the disc is cut with a hacksaw on a metal surface.

- The old disk is removed.

- A new circle is set, i.e. installation is being carried out.

- The lock nut is put in place for subsequent fixation.

Before threading begins, you need to make sure that the disc is properly secured.

The key for the grinder and other criteria for choosing equipment

Regardless of which disc will be used on the grinder, for example, a grinder or with Velcro, you need to select a high-quality tool before work, which by itself will not be able to change direction during work and will not cause serious injury to the upper limbs. A competent choice of equipment will allow you to use it for a long time without problems.

In addition to the standard criteria, you need to pay attention to the availability of additional features.:

- The presence of a soft start (special button), which will eliminate jerks at startup;

- Automatic blocking of brushes on the grinder if power surges occur;

- It will not be superfluous to have automatic balancing of the disk spindle, due to which the runout is reduced during operation (work as on plastic);

- It is mandatory to have the possibility of fixing the start button if continuous operation is required;

- You need the ability to replace the casing without the use of additional devices;

- Availability of stator and armature protection;

- The presence of a key for unscrewing the lock nut.

How to change a disk in a grinder (video)

Bulgarian is a tool needed both in everyday life and in industry. But you need to work with it carefully and correctly in order to eliminate the formation of problems. Coral (vinyl) disc is very practical.

Attention, only TODAY!

Better known under the name "Bulgarian", they are used for various technological processes during construction work and repairs. When choosing a disc for a grinder for wood and rubber, it is necessary to take into account the features of not only the tool itself, but also the objects being processed.

The main characteristics of cutting wheels

Depending on the material of manufacture and design features, there are three main types of circles:

- An abrasive disc for a wood grinder, used to work with various surfaces. Depending on the thickness, the wheel can be cutting and grinding.

- Diamond blade designed to work with stone, concrete and other building materials. Such circles are divided into segmented and solid. The first type, due to better removal of the sludge through the slots and more efficient cooling, ensures high productivity. Such discs can be used when cutting thin metals.

- The usual circle for a circular. However, it is immediately worth noting that it is not recommended to use it for cutting wooden products without work experience, since there are many cases when people received quite serious injuries when clamped into. If possible, when performing such work, it is better to use another tool, such as a jigsaw, chainsaw, etc.

Circle selection

When choosing discs for grinding wood with a grinder, pay attention to such points:

- The size of the circles should not exceed the maximum allowable diameter for which the grinder is designed. A tool designed for discs with a diameter of 125 mm will not be able to work with a 230 mm cut-off wheel for a variety of reasons. Firstly, the speed of movement of the edge of the grinder is significantly exceeded (with a significant increase in it, the disk can simply scatter). Secondly, to work with such a disk, more power is needed than that for which a small tool is designed. Thirdly, to install such a consumable, you need to remove the protective cover, which makes the work more dangerous.

- When working with different types of materials, you should choose a disc that is designed specifically for them.

- Pay attention to the speed of the circle, which is the maximum allowed (or linear speed). These indicators are indicated on the surface of the circle. According to these values, you should also choose the mode of operation of the grinder.

Disc outer diameter

One of the important indicators of a cutting wheel is its outer diameter, which is calculated in millimeters and is unified. For domestic purposes, as a rule, a disc for a grinder on wood 115-230 mm is used.

The diameter of the tool shaft (seat size) is now the same on almost all disks - 22.2 mm, and special intermediate rings are used to install on outdated models of angle grinders.

The most versatile disc is considered to be a grinder for wood 125 mm, 150 mm and 230 mm.

A circle of 125 mm is convenient to use when it is necessary to cut metal fittings and a rod.

A disc for a grinder on wood 150 mm can not only grind and cut metal, but is also able to saw a beam or dissolve a board.

If the diameter is more than 230 mm, then such circles have an industrial purpose.

The disc for the grinder on wood 230 mm has a wider scope, as it can be used in the processing of products from metal alloys of various grades.

Abrasive discs for grinders

As mentioned earlier, for grinders they are divided into cutting (up to 3 mm thick) and grinding (thicker). Despite the fact that the classification is very conditional, there is another significant difference between the discs - the reinforcement of cutting wheels is usually carried out in 2 layers, and grinding wheels are at least three.

Form of abrasive discs

Abrasive wheels differ in their shape. Distinguish:

- Standard flat discs.

- Curved discs (in the form of a plate). They can be used when working in hard-to-reach places. With this wheel shape, the fixing nut is hidden, so grinding work is more convenient.

When purchasing a disc for a wood grinder, pay attention to the marking (for example, A 40 L), which allows you to find out the following information about the product:

- The first letter (or two) indicates the type used. For example: A - corundum, AS - electrocorundum, C - silicon carbide, which is used when working on granite and stone.

- The numbers allow you to find out the grain size of the abrasive. And the larger it is, the faster the work will progress. However, this will worsen the cleanliness of the cut or grinding. A disc with a coarse grain is used, as a rule, for processing soft (non-ferrous) metal, and a disc with a fine grain is used for steel.

- The last letter in the marking indicates the hardness of the bond of the base of the circle (those letters that are located at the beginning of the alphabet mean that the bond is softer). When buying, it is recommended to be guided by the following rule - when working with soft material, use a disc with a soft bond and vice versa.

Almost all manufacturers of abrasive wheels use color marking products. Green is for stone, blue for metal work. It is also worth mentioning the inner landing ring. For cutting wheels, it is made of hard metal, and for polishing or grinding, cutting discs with a softer washer are used.

Diamond cutting wheels for grinders

Depending on the purpose, diamond blades can be divided into several types:

- Concrete. Wheels of this type can easily cope with monolithic, including concrete and reinforced structures.

- Granite. Such discs are used when performing work with especially hard rocks.

- Asphalt. Cut-off wheels are best used in the processing of concrete and, accordingly, asphalt.

- Construction Materials. Discs of this type can be used for cutting ceramics, bricks.

Diamond cutting wheels of some manufacturers are also color-coded:

- Green is granite.

- Blue - concrete, marble.

- Yellow - plaster, tile.

- Gray - ceramics.

Segmented diamond cutting wheels are used to cut materials using the dry method. When using solid discs, a wet cut (water cooling) is used. This is primarily due to the very high heating of the solid surface of the cutting wheel.

There are models that have partial segmentation. These are the so-called turbo disks, in which the slots are placed in the body of the circle (they do not go to the outer edge). Such products can be used at a higher speed than fully segmented ones.

So, by choosing the most suitable cutting disc for a wood grinder in all respects, you can efficiently and safely perform any job.

Safety regulations

When working with an angle grinder, no matter what type of disc is installed, it is necessary to strictly comply with safety requirements.

- The tool must be equipped with a persistent handle and a protective cover.

- All work must be performed in overalls and using personal protective equipment. It is also very important to be very careful when choosing glasses or a mask, because eye damage (according to statistics, this is the most common injury) can be obtained even from small chips or a fragment of the circle itself.

Price

The cost of all cutting wheels for a grinder depends largely on both the model and the reputation of the manufacturer. For example, for a small-diameter wood grinder (125 mm) from Bosch, it costs at least 400 rubles. However, despite this, it is still recommended to give preference to trusted manufacturers, since this tool is with increased danger. Therefore, it is not worth saving on such consumables as a cutting disc.

With Bulgarian.

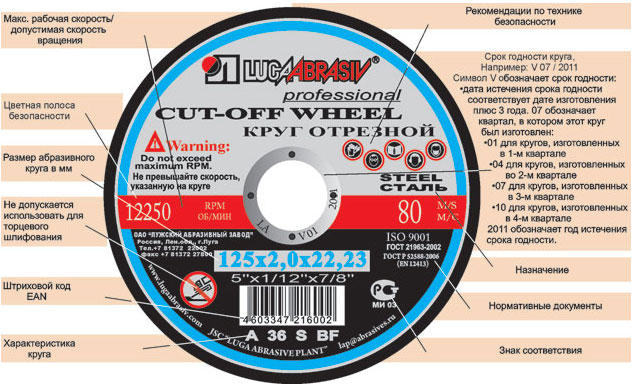

This article will orient you in the world of abrasive wheels and help you accurately and quickly decipher the symbols applied by the manufacturer.

Abrasive wheels are specially marked in the form of inscriptions and / or colored marks and contain:

1. Circle type

In theory, there should be a digital designation: 1 - straight profile, 41 - cutting discs, 42 - discs with a recessed center, but in practice it will be an inscription in Russian and / or English: "cut-off wheel" - cutting wheel, grinding wheel - grinding wheel, petal wheel.

2. Dimensions of the circle

On the manufacturer's website (see table below) it is indicated as follows: D - outer diameter, T - height, H - hole diameter.

However, in practice, the format will usually be: outside diameter x thickness x inside diameter.

Or even something like this:

3. Material for processing which the disk is intended for is indicated by an inscription on a circle (“metal” or “steel” - for metal processing, “concrete” - for working with concrete), a color mark (blue - steel, green - concrete).

Also, sometimes a graphic image of the material is additionally applied, which saves us from having to read the inscriptions once again. On the circle shown in the picture above, the inscription metal and the image of sheet metal, metal pipe, roofing metal sheet and channel clearly demonstrate the material that can be processed.

4. Abrasive material from which the circle is made. Conventions are available in the table below.

5. Graininess. Abrasive particle sizes. This parameter is indicated on the circle in conventional units and indicates the abrasive fraction based on international marking standards. Also, variations from one edition of GOST to another are possible here.

6. Hardness. See table.

7. Bundle type Bakelite, ceramic or synthetic rubber is used as a binder.

ceramic bond- V (K - old designation). In the case of a ceramic base, the tool has high refractory, water-resistant and chemical characteristics, which qualitatively preserve the working edge. However, such a disk for an angle grinder is sensitive to mechanical shocks and bending loads. Vitrified bonded wheels are used for almost all types of grinding except roughing.

bakelite bond- B (B is the old designation). Considering the bakelite base, I would like to note that such circles for grinders have higher rates of elasticity and resilience than ceramic counterparts. The disadvantage of such a binder is the low resistance to alkaline components included in the liquid for cooling.

In addition, Bakelite-based wheels are weaker than ceramic counterparts in terms of abrasive grain adhesion and, therefore, can mainly be used for flat grinding. Discs for grinders on a bakelite bond are used for manual work on rough peeling or on suspended wall surfaces. At the same time, bakelite circles have a polishing effect. For the purpose of cutting steel products, a soft bond and a fine abrasive are used. In turn, for non-ferrous metals, it is advisable to use a solid bond with a coarse abrasive.

Vulcanite bond is a vulcanized synthetic rubber. The abrasive wheel is marked with the letter (R). The old designation is (B). This option is exotic and is extremely rare.

8. Max. speed in which the disk can be used. They vary from 6,600 to 13,300 rpm. Important setting! If it is neglected, then the circle during operation may shatter into separate fragments.

9. Accuracy class AA, A and B. AA - high accuracy of geometric parameters A - Intermediate option. B - for less responsible operations.

10. Manufacturer. I guess no explanation is needed here.

11. Expiry date. The expiration date is applied by the manufacturer on the metal part of the mounting hole from the outside. The expiration date is the date of manufacture plus 3 years. The quarter is indicated by the letter V. The number indicates the month.

Important! Pay attention to the expiration date.

12. Safety pictograms. I guess that no one cares about them, but in addition to the banal “put on headphones”, something really worthwhile can be applied. For example - do not use for face grinding.

An example of decoding from the website of OJSC AbrazivKhimSbyt

cutting wheel size 125mm, thickness 2mm, bore 22.23mm, made using normal electrocorundum grinding grain, grit R36. On a bakelite bond with the presence of reinforcing elements.

Table

|

4. ABRASIVE MATERIAL |

||

|

ELECTROCORUNDUS NORMAL |

||

|

ELECTROCORUNDUM WHITE |

||

|

ELECTRIC CORUNDUS ZIRCONIUM |

||

|

SILICON CARBIDE BLACK |

||

|

SILICON CARBIDE GREEN |

||

|

5. GRAIN |

|||

|

GRINDING |

|||

|

6. HARDNESS |

|||

|

VERY SOFT |

|||

|

H, I, J (M1, M2, M3) |

|||

|

MEDIUM SOFT |

|||

|

O, P, Q (CT1, CT2, CT3) |

MEDIUM HARD |

||

|

VERY HARD |

|||

|

EXTREMELY HARD |

|||

|

7. LINK |

|||

|

CERAMIC |

|||

|

BAKELITE |

|||

|

BAKELITE WITH AVAILABILITY |

|||

|

BAKELITE WITH GRAPHITE |

|||

|

8. WORKING SPEED |

|||

|

twenty; 25; 32; 35; 40; fifty; 63; 80; 100 m/s |

|||

|

6,600 to 13,300 rpm |

|

9. ACCURACY CLASS |

|||

Remembering all of the above is optional. Bookmark this page and have a look just before buying, for example from your phone.

If you are a man with hands, and you have a grinder, consider yourself lucky.

With its help, you can perform a lot, improve your life, save a lot of money.

However, for successful work, you will need not only the grinder itself, but also disks for it.

Types of discs for grinders are different - for woodworking, metalworking, rust cleaning and many other things.

The official name of the grinder is an angle grinder, or angle grinder.

It is called so because it was originally used to work with inaccessible internal large-sized parts in production.

In the future, it began to be used for other works, mainly for cutting metal and stone materials.

Most types of grinder discs are also designed for cutting.

Bulgarians are different. Their discs have different sizes - the smallest is 115 mm in diameter, the largest is 230.

Most often they use a tool with discs of 230 and 125 mm. They are the easiest to find on sale. There are reasons for this - the smallest discs with a diameter of 115 mm wear out very quickly, they have little working, a significant part of the diameter is eaten up by the dimensions of the tool and the mounting hole.

Therefore, where it is necessary to perform precise work, holding the grinder with one hand, use a tool for the 125th disc. And if you need to cut a lot, long, thick material - you need a powerful tool with high performance. This is exactly what a grinder is for 230th discs.

All disk sizes:

- 230 mm

- 180 mm

- 150 mm

- 125 mm

- 115 mm

During operation, the disc is ground, and its diameter changes. This can happen until the disk breaks or until its diameter becomes smaller than the diameter of the grinder body.

A disc of smaller diameter can always be put on a larger grinder. This is obtained because all angle grinders have the same bore diameter - 22.2 mm. And the thread of the stud for fixing is the same - M14.

There are discs with larger diameters. However, they are not intended for grinders. A more powerful tool can be manual, but more often it is used for machine tools, for concrete cutters, and other machines that are not designed to be kept in.

Large discs have a higher cutting speed, longer life, but they are more likely to break, therefore they are not intended for hand tool- too dangerous.

There are other manual ones that, in principle, can use types of discs for grinders and surface grinding.

These are the so-called concrete grinders.

They can use discs with a diameter of 230 mm. However, their main goal is not to work with a radial surface, that is, the edge of a circle, but with its plane. The main consumable for them is cup grinding wheels.

Combined discs have grooves along the edges of a curved shape. They remove dust from the cutting area. They can be used for all types of cutting, more productive than others, but they have more wear per meter of cut.

Wood discs and safety

On sale you can find many other discs for the grinder - for example, numerous types of discs for the grinder, for cleaning concrete joints, for polishing, etc.

As for wood discs, we can definitely say that this is a gross violation of safety regulations, which has already led to many victims.

As for other disks, they are not directly dangerous for the worker.

They are dangerous for the tool - if the grinder works with a load not radial, but along the axis of the disk, its bearings fail. Repairs won't be cheap.

There are some other types of discs, the use of which is not fatal for the grinder. These are disks with a cork brush located radially, and disks with skin petals for, also located. However, they can be used if their width is small. With grinders for concrete, you can use, in principle, any discs, but this is no longer a grinder.

The video provides an overview of the disks for the angle grinder:

Noticed an error? Select it and click Ctrl+Enter to let us know.