Bulgarian is a very necessary and useful tool. Due to the fact that there are a large number of different nozzles for it, it can be used for cutting, grinding and polishing a wide variety of materials: metal, stone, wood, etc. In this article I want to tell you what discs are for grinders so that you can have an idea of what kind of work can be done with this tool. In addition to discs, consider various attachments.

It is worth noting that grinders of different sizes will require discs of different sizes. Also, keep in mind that each wheel or attachment is only designed to operate at a certain RPM, so always keep that in mind when choosing.

Now let's go directly to the topic of the article.

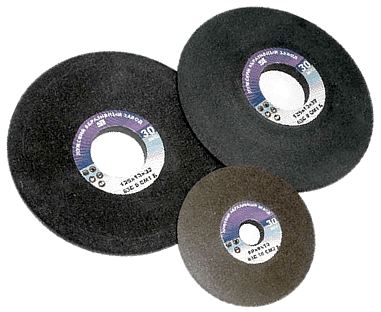

Abrasive discs for metal cutting

These circles are perhaps the most popular to use. After all, most users use the grinder just mainly for cutting metals.

Here, when choosing, the value must be given to the thickness of the disk, as well as to the one who produced it.

The thickness, which varies from 1 to 3 mm, affects the cutting speed - the smaller it is, the faster the cut. In addition, sometimes it is necessary that the incision is as thin as possible, so a thick circle is not used. But it is worth noting that thin circles are consumed faster than their thicker counterparts. In this regard, if the cutting speed is not particularly important to you, you can buy products for 2.5-3 mm.

As for manufacturers, this point is important because of the uneven quality of products from different companies. If you take a product from such famous brands as Bosch or Makita, then they will be spent much more slowly. The price of such discs, however, is quite high. Therefore, for one-time work, you can get by with an inexpensive option, the most popular of which is the products of the Luga plant.

Abrasive discs for stone cutting

This type differs from the previous ones in the composition of the abrasive, therefore it allows you to cut not metal, but stone. Otherwise, all the points that matter for metal discs will also be true for stone circles.

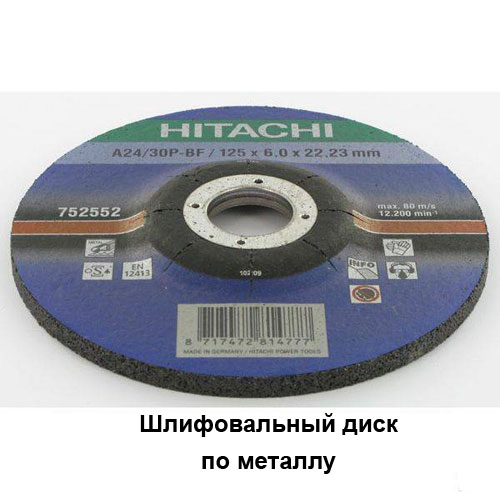

Abrasive discs for grinding metal

They have the same composition as discs for metal. The difference will be that their thickness will not be 1-3, but 6 mm. They are used, of course, no longer for cutting, but for grinding. For example, they are convenient to walk along the welds to level the surface.

With regards to manufacturers, things are the same here as with the previous types.

Abrasive discs for grinding stone

Here the story is similar to the previous paragraph, only the composition of the abrasive is already designed to work with stone.

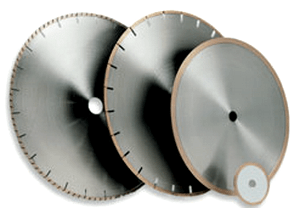

Diamond blades for stone cutting

It is most beneficial to cut stone materials with such equipment, since, unlike abrasive, they do not decrease in diameter during operation, and in general they last much longer. Even despite the relatively high price, their use is more profitable.

There are three types diamond circles for angle grinders - segment, turbo and turbo-segment. In the first, the edge has cuts, because of which the circle is divided into segments - hence the name. The second ones have notches along the edge, giving the appearance of a turbine. Apparently that's why they're called that. Still others combine both notches and incisions.

Notches and notches are made for better cooling in order to avoid overheating. It should be said that diamond blades are also smooth, but they require cooling with water, which is why they are used only on tile cutters, since water can be brought to them. True, the Chinese began to make smooth diamond cutters for grinders as well - in this case, you have to work with frequent interruptions. Reputable manufacturers produce them only for tile cutters.

I also note that segmental circles cut faster, but the turbo has much fewer chips on the cut, although it cuts more slowly.

As for quality, it varies from manufacturer to manufacturer. There are also products from reputable companies such as Bosch, and there are also inexpensive Chinese options.

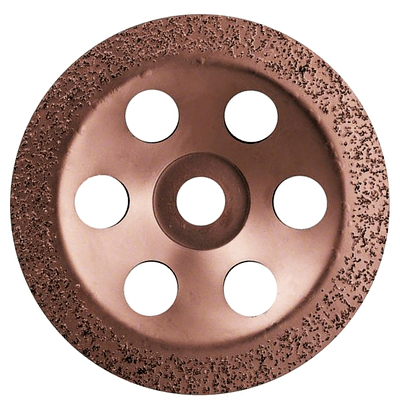

Diamond discs (cups) for grinding concrete

Concrete sometimes has to be not only cut, but also polished. This is where diamond cups come in very handy. Thanks to them, it turns out to quickly process large areas, since their working surface is rather big.

In general, these cups are best used on special electric grinders. They differ from grinders in that they have a different casing that allows for effective dust extraction with an industrial vacuum cleaner.

However, this tool is quite expensive. For this reason, many get by with a grinder, if it is not critical that a dust cloud will form.

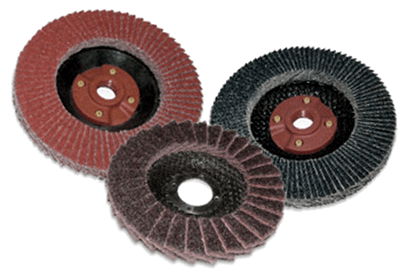

Flap discs for grinding

These circles are a base to which sandpaper petals are attached along the edge of the circle. The sandpaper here can be of various grain sizes - large for quick and rough work, fine for fine finishing.

They are most often used for sanding wood, but no one forbids sanding surfaces from other materials with them. Due to their small thickness, they manage to crawl into rather narrow places.

One of the most common applications of such a wheel is sanding the logs of a log cabin of a bathhouse or a house.

Their wear occurs relatively slowly, so one copy can process quite large surfaces.

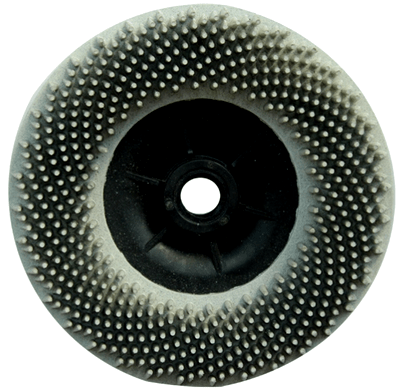

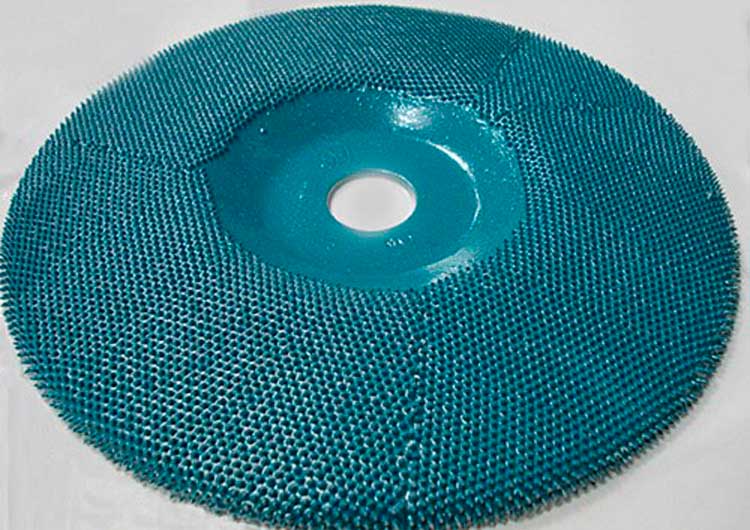

Round nozzle with Velcro

Special circles of sandpaper can be attached to these nozzles with Velcro. With their help, you can quickly grind flat surfaces of a large area. Unlike petal discs, such a nozzle works on the entire surface, and not just on the edge. Therefore, the processing speed is higher.

True, with its help it is not very convenient to work, for example, on concave and other non-flat surfaces. It is better to use petal circles on them.

There are also felt polishing wheels for these nozzles. True, it is not recommended to use them on angle grinders, since they have too high a rotation speed. There are special polishing machines for felt wheels. They may look like a grinder, but differ in that they have a maximum rotation speed of about 800 rpm, while grinders, even with speed control, have a minimum speed of 3000 rpm.

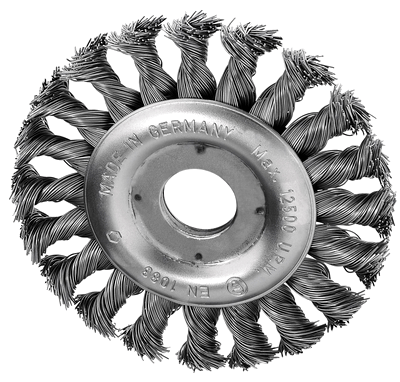

Corsets

These are quite popular nozzles, which are a base with pieces of wire attached to it. The wire can be fluffed or twisted. Its thickness can also vary to give different rigidity.

There are quite a lot of shapes and sizes of corsets. They are used for various purposes, mainly for metal processing. They can clean the surface of old paint or rust. They can also be used as a final finish for a metal product, when the surface after brushing is no longer processed.

These are the main discs and nozzles that can be used on angle grinders. Using them, you can do completely different work with one tool. I hope this information was useful to you. And this concludes the article - see you soon!

An angle grinder, a power tool familiar in working with metal, is also effectively used for processing other materials. The question "Is it possible to cut a tree with a grinder?" Many owners of this useful power tool are asked. There is no direct answer to this question.

There are special cutting discs on wood, designed for such work, but this is rather an exception. In addition, such a disk is not suitable for every angle grinder.

Let's consider several options.

These cutting discs can be used to cut boards up to 40 mm thick, with extreme care. Rules, non-observance of which lead to injuries:

The saw blade has a metal base and a chainsaw chain fixed around the perimeter

- It is strictly forbidden to remove the protective cover if the diameter of the disc exceeds the dimensions of the casing - your angle grinder cannot be used;

- The angle grinder must run at the RPM indicated on the disc. Otherwise, the chain may jump off and its components will fly apart;

- Safety goggles and thick gloves are required. It also does not hurt to wear thick canvas clothes.

IMPORTANT! It is strictly forbidden to use ordinary circular saw blades on an angle grinder.

The same applies to diamond cutting discs for concrete. They are unsuitable and dangerous for sawing wood products. Firstly, the work efficiency is extremely low, especially considering the cost of the disk. Secondly, you can simply burn the workpiece.

And finally - such a disc can jam in the cut at any moment, and you will get hit by the grinder's body.

Here is an example of a disc for a grinder, with which you can saw a tree with extreme care.

The design of the circle provides protection against jamming with the help of side teeth that expand the width of the cut. The disk has a diameter of 115 mm, and its dimensions allow you to work without removing the protective cover.

The wood disc fits completely under the protective cover

Some homegrown "masters" fit standard circular saw blades under, the work is done with the protective cover removed. Most often, such experiments end tragically. The unfortunate master receives severe injuries, and a fatal outcome is also possible.

At the same time, the construction markets are full of offers of saws for a grinder for wood. Sellers will assure you that in the hands of a professional, the use of such a tool is completely safe. This statement is true as long as these very hands are safe and sound.

No self-respecting store will sell you a cutting-off, supposedly suitable for angle grinders, because if the buyer is injured, the seller may face criminal penalties.

Reasons not to use a circular saw with an angle grinder:

- The disk is designed for low speeds, the metal of the circle is hard, but brittle. During operation, it may shatter into pieces or soldered teeth may fall off the disc, which scatter at the speed of a bullet;

- The tree has a viscous structure, so the teeth bite unevenly. Due to this, the instrument bounces and vibrates. It is easy to lose control of the tool and cause serious injury to yourself;

- If the disc is jammed (and this situation will definitely arise when working with wood), the grinder will simply be pulled out of your hands. The further behavior of the turned on tool with a rotating toothed disk is unpredictable;

- During woodworking due to uneven loads, the angle grinder overheats and may fail.

The only way out is to make a stationary sawing machine, with a securely fixed grinder, as the master did in the video lesson.

It does not make sense to consider the option of cutting wooden blanks with the help, since it will still not work to effectively use such a disk. This is tantamount to trying to saw through a log with a file. True, the security will be at a high level.

Rough processing of wood with angle grinders

However, it is possible to process wooden blanks with an angle grinder. It is only necessary to use special factory-made nozzles and strictly observe safety precautions when working with an angle grinder.

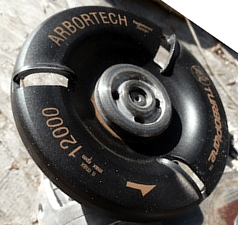

The use of angle grinders as a planer

When roughing logs, for example, for the construction of a log house, special planer disks are used. This is a relatively safe way to process wood, subject to the rules of operation. It is a mechanized replacement for a carpenter's axe.

Arbortech TURBOPlane disc planer. Disc can be re-sharpened

The nozzle is used without a protective casing, since its destruction during operation is excluded. It is forbidden to use such a disc with it turned up. When working on a grinder, a handle is required to hold the tool with both hands.

Since during the cleaning of the tree, large chips fly out of the working area - you need to have tight overalls and protect not only your eyes, but also your face. A positive side effect of this tool is that you can easily chop chips and large sawdust for a home smokehouse.

Roughing discs

To remove the bark from logs and give them the shape of a primary blank, there are special peeling nozzles for angle grinders.

An example of a peeling nozzle using a chain from a chainsaw

With the help of such a chain wheel, it is possible not only to clean the trunk from bark and branches, but also to give the workpiece the required shape for subsequent processing with a more accurate tool. Such a device can easily replace an ax for cutting a bowl in a log during the construction of wooden log cabins.

You can use this disc as a cutting wheel, but the cut will be torn and the loss of wood is too high, the cut thickness is several centimeters.

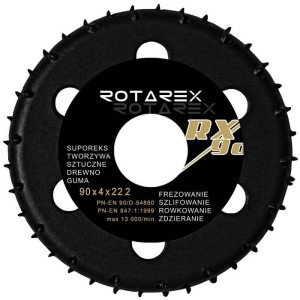

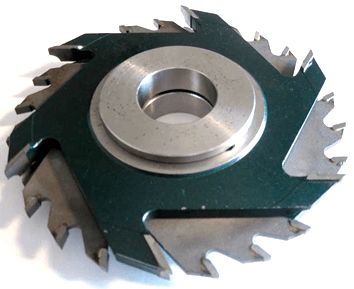

Wood cutters for grinders.

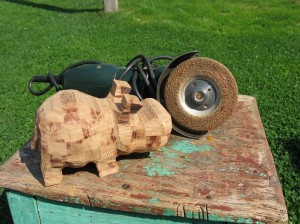

After roughing, you can proceed to a kind of rough milling of a wooden blank. There is a special nozzle for this.

Grinding disc with coarse abrasive

Abrasives on the disc can be of any size, it all depends on the purpose. Using such cutters, you can give the final shape to the workpiece. Some craftsmen use these nozzles for finishing wood. The result can be quite interesting - just a dream of Papa Carlo.

Wooden hippopotamus made using a peeling wheel

In fact, such a disk is a mechanized rasp. This is a fairly safe tool that does not require special precautions and special requirements. It is enough to protect the eyes and respiratory organs.

IMPORTANT! For the banal sawing of boards and logs, there is a large assortment of inexpensive circular, chain and reciprocating saws. Don't forget the electric jigsaw!

Milling with a grinder

Another dangerous, but approved tool for use with safety precautions, is for angle grinders.

The installation diameter of the cutter for wood is suitable for the landing diameter of the angle grinder

With the help of such a cutter, you can make grooves, roughly level the edge, cut out bowls for a log house, and even saw blanks. The design excludes jamming and rejection of the tool on inhomogeneous wood. Before use, be sure to read the instructions, especially the sections on maximum speed and direction of rotation relative to the position of the angle grinder.

IMPORTANT! When working with such nozzles, it is forbidden to remove the protective cover.

The range of cutters for the grinder is not inferior to the choice of nozzles for manual router. Of course, you will not achieve the same exact processing, but you can choose the right nozzle to give the workpiece any shape.

Disc grinder with a high tooth

How to properly and effectively grind wood with a grinder

After giving the workpiece the required shape, you can proceed to the finishing, final processing. Let's remember the correct name of the "grinder" - an angle grinder.

Despite the fact that angle grinders are most often used as a cutter, its main purpose is grinding and polishing. And for woodworking in this capacity, the grinder is an indispensable assistant.

Consider nozzles for various types of grinding wood products

cord brushes

Designed for rough grinding and leveling the surface of wood. With the help of such a tool, the workpiece is given the final shape.

Wood disc for coarse sanding

end discs

Are intended for alignment of an end face of preparation. Most often, such a need arises with oblique cuts. The operation of this disk resembles a file, only the performance is an order of magnitude higher.

End disk for aligning the edges of the workpiece. Installed on the grinder

Flap sanders

The most common segment of devices for grinders. They are used for processing any materials, including wood.

Flap sander

Depending on the size of the abrasive, either an uneven layer is quickly removed, leaving the surface rough, or all irregularities are smoothed out without removing a large thickness. Proper use is a gradual transition from a coarse-grained fraction to a finer one. Due to the rigid base, they allow you to apply a lot of pressure on the workpiece, to increase efficiency.

Structurally, they consist of trapezoidal sandpaper petals overlapped with an overlap of three quarters. Due to this, when erasing the edges, the next layer works. Nozzle wear is quite slow. For cleaning wooden products of complex relief shape, a petal nozzle with a radial arrangement of sandpaper strips is used.

The tool requires certain skills. With careless handling, it is easy to “scrape” the protruding parts of the workpiece. Before use, it is recommended to practice on unnecessary pieces of wood.

Sanding disc with radial sanding paper

Grinding wheel with Velcro

For most angle grinder owners, it is this nozzle that is associated with the concept of a grinding disc for wood.

A more versatile wood sander is hard to come by. Attached to the work surface is a round sandpaper with a special coating, and you can start grinding surfaces of any size. It is enough to purchase such a nozzle once, and all that remains is to change the emery wheels with any grain size.

circle on the grinder for attaching sheets

Abrasive wheels with different sizes of abrasive

The efficiency of work in comparison with a conventional manual grater is several times higher. With proper skill, such a disk can process edges no worse than a molding cutter. And for updating furniture with cracked varnish or paint, you won’t find a better tool. Surfaces can be cleaned with virtually no reduction in thickness. After painting, the product will look like new.

Without a special polishing machine, with the help of such a nozzle, parquet can be scraped off. True, it will be necessary to take care of the removal of dust and sawdust. And after varnishing, the floors can be polished using the same angle grinder and special polishing nozzles.

With proper use of an angle grinder, this device becomes a universal tool that can process any material. In this case, the correct selection of nozzles is the main factor.

With the help of a grinder, you can perform many different operations using different disks and nozzles: peel, sharpen, polish, and also perform other types of work where you can use the rotational movement of the tool.

Types of nozzles

There are many different attachments and attachments used when working with an angle grinder. Consider their main types, design features and application.

Cutting discs

These are the most common nozzles, of which many types are produced. With the help of them you can process any material. Discs for metal, stone, wood became popular among them.

- Cutting discs for metal vary in diameter and thickness. By diameter in the distribution network, you can find discs with a diameter of 115 - 230 mm. The thickness of the discs ranges from 1 to 3.2 mm, depending on the diameter. These dimensions also depend on the speed of rotation and the load applied to them.

- Discs for stone processing differ from other types only in the abrasive materials from which they are made. The rest of the parameters are similar.

- Wood discs. The use of such discs is very dangerous, if you work carelessly, you can get injured. Such discs are essentially saws. It is forbidden to remove the protective cover from the angle grinder. It is better to use a blade for sawing wood with a fine tooth, and not to use a large feed. The best option for using such a nozzle for an angle grinder is the use of special devices for stationary fixation of an angle grinder.

- diamond disc is universal, as it can cut any material. Such nozzles have gained great popularity in cutting tiles, stone, concrete and granite. For each material, you can choose your own type of disc. Some models have a slotted cutting edge, while others are solid, and they are also available with fine or coarse diamond coating, depending on the application. For example, discs for cutting stone are solid, and for cutting concrete with transverse slots and fine spraying.

By appearance it is difficult to determine what the disk is intended for, therefore, when buying, you should familiarize yourself with the characteristics of the disk indicated on the package.

Polishing and grinding

There are many types of such circles. They can be cloth, sponge, felt and with a replaceable sanding sheet.

To work with them, it is necessary to use special pastes with fine abrasive, as well as various liquids. Fine abrasive wheels are used for cleaning and rough grinding. The use of grinding discs makes it possible to bring the surface of any material to the desired roughness. Such nozzles for the grinder are used for polishing the car body.

Peeling and sharpening nozzles for grinders

These disks can be divided into the following types:

- Twisted cones.

- Sharpening abrasive.

- Rough diamond.

- Twisted cutters used for peeling stone and metal surfaces when removing old cement mortar or dried paint. The cone consists of two steel cups. Along their perimeter are steel wire brushes. Depending on the type of processing, the wire may have a different diameter.

- Sharpening discs serve for sharpening of the cutting tool, cleaning of welded seams. Most often, such nozzles are used on low-power angle grinders, since it is more convenient for them to work with such discs. Grinding discs differ from cutting models in shape and thickness. In the middle part of the disc there is a recess that allows sharpening with a flat surface of the disc. Its thickness is usually at least 5 mm.

- Roughing diamond discs they are similar in design to grinding wheels. The difference is that diamond disc works only with its peripheral part, on which there are cutting edges. Also, the diamond grinding disc is not suitable for metal processing. It is used for peeling stone, concrete and other similar materials. For peeling off hardened cement mortar, a diamond blade is the best fit.

Attachments for the grinder greatly increase the functionality of the grinder. Bulgarians are widely used in construction and many other areas. And together with various nozzles, they become universal equipment.

Wood sanding attachments

The grinder can be used for wood surface grinding, tree cutting. To do this, use special types of nozzles for certain types of work. Before starting surface treatment, it must be marked.

After grinding, circles from the disk remain on the surface. This is noticeable after coating the surface with varnish or paint. This is the peculiarity of the work of the grinder. Therefore, it is additionally necessary to go over the surface with sandpaper by hand. You need to work on wood with a grinder carefully, without making much effort, do not use thin circles, properly fasten them.

To do right choice nozzles for the grinder, consider their specifics of use and various modifications.

Coarse Handling Tools

planer disk can completely replace a hand planer.

To perform rough processing of logs during the construction of a house, the processing of fence posts, such a nozzle will be an indispensable assistant.

Features of its use are:

- May only be used with a grinder equipped with a second auxiliary handle. For safety reasons, the angle grinder must be held with only two hands.

- It is allowed to remove the protective cover, since the body of the nozzle is one-piece, and the probability of its destruction is very small. However, protection from flying chips is required: gloves, glasses, clothing.

Roughing disc designed to remove the bark of a tree and rough processing of the workpiece.

If you have certain skills in the tree array, you can perform a selection with such a disk. When building a log cabin, a grinder with a peeling head is a good alternative to a conventional axe.

It is also possible to cut a board with a peeling disc, but the cutting width will be large, and more sawdust will be formed.

Milling attachments

There are two types of such nozzles: discs and cutters.

Disks produced in different versions. Their difference is the grain size of the abrasive material.

These abrasive discs are similar to the surface structure of a hand rasp, with the difference in processing speed. With dexterity and acquired skills, such discs are used for finishing wood.

Wood cutters produced in a wide range. They differ in size, location and shape of the teeth.

Cutters are designed for:

- Samples of various grooves.

- Cup cutouts.

- Rough alignment of edges.

- Sawing small pieces of wood.

Features of using cutters:

- It is forbidden to remove the protective cover when working with the cutter.

- It is allowed to use the cutter only for the work specified in the instructions for it, with the recommended rotation speed, and other instructions.

Sanding attachments

The main purpose of the grinder was originally grinding, as evidenced by its correct name - an angle grinder. Therefore, wood grinding, as an operation, is the best fit for a grinder. Let's consider the main nozzles for the grinder, with the help of which wood is polished.

Cord brushes are mainly used for primary grinding of wood, when it is necessary to even out surface irregularities.

Name end discs speaks of their purpose. They process the ends of wooden parts. End discs are especially suitable for corner cuts.

Petal nozzles are applied in a specific sequence of processing operations. Therefore, they must have several pieces, a separate nozzle for each operation. Grinding starts with a coarse disc, then the size of the abrasive is reduced, and nozzles with a finer abrasive grain are installed.

grinding wheels are a universal attachment to the grinder. One circle is enough to complete all stages of grinding. Such a circle is made of a metal base, on which circles with different grain sizes of the abrasive are fixed. Wheels as they wear out can be easily changed to others, they are consumable items. The base of the nozzle can work for a long time.

Purpose:

- Surface cleaning before painting.

- End and edge processing.

- Scraping parquet floors.

- Sanding wooden surfaces.

Wood polishing nozzles

Wheels, discs and brushes are used to polish wood. Their working parts are made of fine sandpaper, felt, sponge and other materials.

Consider the main types of nozzles for polishing. There are many varieties of polishing nozzles in the distribution network, so there are no particular problems with finding them.

- It is forbidden to use discs from a circular saw with a grinder when fitting parts before grinding, since the grinder is a high-speed tool. In this mode of operation, the saw teeth do not withstand long-term operation and are destroyed, flying apart at high speed. This is a safety violation.

- Some circular saws are large, so the craftsmen remove the protective cover, which is also very dangerous.

- Frequent mode changes contribute to overheating of the grinder motor, so you should take breaks in work to cool it down.

- Due to the loose structure of the wood, the saw blade may jam. Therefore, there is a possibility that the angle grinder will break out of the hands, which can lead to human injury.

Wood processing by a grinder is carried out only in the form of rough processing, grinding, and other surface work. And for cutting and cutting sheet materials, it is better to use tools specially designed for this.

An angle grinder, if you know and correctly use all its capabilities, is a truly universal device that lends itself to almost any material. And if we are talking about processing wood on a large scale, then the “grinder” is much more effective than manual abrasive tools and fixtures. The main thing is to choose the right nozzle. This article will help you understand their main modifications and specifics of application.

Rough cleaning of wood

planer disk

Such a nozzle almost completely replaces this hand tool.

An irreplaceable thing, if it is required, for example, to make a rough processing of a log - when erecting a log house, preparing fence supports, and so on.

Application Features:

- In this case, the protective cover can be removed. Such a nozzle is one-piece, and its destruction does not occur. But protection from flying wood chips (glasses, tight clothing, gloves) is required.

- It is allowed to work only with a “grinder”, in which a second handle is provided (or installed). The angle grinder must be held when roughing wood with both hands.

Peeling disc

The main purpose of such nozzles is to remove the bark from the wood, to trim the workpiece. If the "grinder" is in capable hands, then with such a device you can make a sample of the material. For example, if you need to cut a bowl. If a log cabin is being built, then an angle grinder with such a nozzle perfectly replaces a carpenter's ax.

In some cases, a peeling disc can be used to cut. True, the cut will be wide, and there will be a lot of waste (chips, sawdust).

Milling

Disks

These nozzles are available in various designs. The main difference between the devices is the size of the abrasive grains.

They are not much different from rasps in terms of specific application. The difference is only in the speed of the technological operation. With certain skills, it is advisable to use these for finishing wood.

cutters

They are, and specially for wood. The assortment is significant, since nozzles of this type differ in the configuration, location and size of the teeth.

Purpose of cutters:

- Selection of grooves.

- Edge trimming.

- Cup cutout.

- Sawing (for wooden blanks of small section).

Application specifics:

- When processing wood with such nozzles, it is forbidden to dismantle the protective cover.

- Each product has instructions. It clearly indicates for what types of work this nozzle is intended, the recommended speed of the grinder, and so on.

wood sanding

If you decipher the abbreviation angle grinder, then it is clear that it is the finishing that is the main purpose of the grinder.

cord brushes

They are mainly used for primary (rough) grinding of wood, when it is required to smooth out the irregularities of the sample.

End disks

The names speak for themselves. Such nozzles process the final parts of wooden blanks (cuts). Especially effective if you have to deal with angular (oblique) cuts.

Petal nozzles

The most used grinding devices for the grinder.

Such nozzles are applied sequentially, so several of them will be needed to process wood. Grinding begins with a disc with a "coarse" abrasive, and gradually the size of its grain must be reduced. Consequently, the devices in the process of working on the "grinder" periodically change.

grinding wheels

The most universal adaptation to the "Bulgarian". It alone is enough for varying degrees of grinding. The nozzle itself is a metal base on which circles with one grain or another are attached. They are easy to change, or as they wear out, or in the event of a transition to another area of work. Therefore, only circles are consumables. The nozzle itself is used indefinitely.

![]()

Application specifics:

- Wood grinding.

- Parquet scraping.

- Edge and end processing.

- Cleaning wood before painting.

wood polishing

For these purposes, brushes, disks, circles are used. Their "working elements" can be made of sponge, felt, fine-grained "sandpaper" and a number of other materials.

The article provides examples of only the main types of nozzles for the grinder. There are quite a few products of this class, so it is easy to choose the best option for processing any wood. The author hopes that the information provided will help the reader in this.

On a note!

Wood processing also means its cutting (sawing). Sometimes, in the manufacture of piece parts, it is necessary to adjust them at the installation site even before starting to grind the sample. Some "craftsmen" (and there are many of them among friends and on the Internet) are advised to use for such operations. It is strictly forbidden! Here are just the main reasons why this should not be done.

- "Bulgarian" - a high-speed machine. And although the metal from which the cutting discs are made is durable, in this mode it does not withstand for a long time. More precisely, cutting edges (teeth), which are fixed by soldering. With intensive work, they fall off and scatter to the sides, and with great speed. The consequences are easy to predict.

- Not all discs are suitable for installation on angle grinders in terms of size (primarily, outer diameter). So, you have to dismantle the protective cover. The same thing - you can forget about the safety of the employee.

- The structure of wood (even hardwood) is quite loose. Therefore, it is highly likely that the saw blade may jam due to constant vibration. How the “Bulgarian” will behave in such a situation, given its power and speed, no one will undertake to predict. But the fact that it breaks out of hands quite easily is unequivocal.

- Constant changes in the mode (for the same reason - the viscosity of the lumber) lead to a systematic overheating of the angle grinder engine. With this use, the "grinder" will not serve for a long time.

That is why wood processing with its help is carried out only superficially - rough cleaning, grinding, brushing. And for cutting, you should use sawing tools and mechanisms (hacksaw, circular saw, electric / jigsaw, and so on).

The original - and main - purpose of the angle grinder was, of course, the grinding of various materials using a special disk that rotated at high speed. They used the "grinder" mainly to eliminate flaws in construction: they cleaned cement sagging and metal welds. It took quite a bit of time, and the builders were convinced that this miracle machine processes both wood and other materials. The main thing is to choose the spindle speed of the grinder and the “correct” disk.

Types of grinding discs

The most important thing to know when choosing discs is two parameters: what kind of material these devices will be used for grinding, and the depth of processing. Sometimes it is required to peel off the top layer, with paint residues, and sometimes carefully polish the product, discs are used in these cases different. Main varieties:

- grinding discs for a wood grinder are a great help for a home craftsman and a small furniture production. You can update old furniture by re-lacquering it, or smooth out the bumps that have arisen during the processing of furniture components;

- grinding discs for concrete for grinders help to make even and accurate cuts in a concrete wall for laying engineering communications. And there will be no superfluous such goods during construction in a popular way - by casting a concrete reinforced base of the structure;

- grinding discs for grinders for metal are probably in the arsenal of a service station, a master welder and enterprises engaged in the manufacture of metal structures. Moreover, there are different types of discs in stock - this is, first of all, convenient. Yes, and the pocket does not pull the stock.

Characteristics

Separately, it is worth noting that the grinding discs are much thicker than their counterparts - cutting wheels. They will also cope with a piece of metal, only they will be erased much faster, and the width of the cut will be more than impressive - up to 5 mm.

Grinding discs for grinders, the price of which is slightly higher than abrasive cutting wheels, must withstand very significant lateral loads, hence the thickness. They can be the basis on which the abrasive material is attached.

For the final finishing of the product, you may need a cloth or felt grinding wheel, and a special abrasive paste.

Main characteristics:

- circle diameter;

- degree of processing;

- What material is this sanding disc for?

How to use grinding discs

Both the mounting option and the protective measures are the same. The method differs only in that it is not the sharp edge of the disk that becomes the working part, but its entire horizontal plane.

The principle of operation is gradual, slow processing of the material. Strong pressure or a sharp movement can damage the grinding disc, especially at low spindle speed grinders.

Where to buy grinding discs inexpensively in Moscow?

You can buy grinding discs, the price of which is affordable, at the nearest market. Remember the seller well - it will be possible for him to make a complaint about the low quality of cheap discs. On the website of the Startool online store, grinding devices are sold more expensive, but these are good quality discs, and they will undoubtedly pay off in work. We only sell quality products.